Packaging and Palletising

Manufacturers in the packaging & palletising industry have come to expect the best performing robotic solutions available globally.

Mexx Engineering® is one of the few robotics and automation companies in Australia. We are known for designing and manufacturing complete lines that are built to handle a range of functions from upstream processing, sorting and packing through to the end of line palletisation.

Mexx Engineering® can streamline the packaging & palletising industry using innovative and versatile systems such as:

- Autobagger System

- Bi-directional Palletiser and Depalletiser System

- Bottle Palletiser System

- Debagger System

- Conveyor System

- Continuous Bottle Turner

- Vision System

The implementation of robotic automation within the packaging & palletising industry offers incredible potential for improved safety, quality and productivity by enhancing process monitoring and control.

Packaging and palletising machines manufactured by Mexx Engineering® are user-friendly. It is built with combined controllers and instinctual human-machine interfaces. They’re brainier with advanced sensing and software, and more proficient at handling product variants.

Robotic automation through Mexx Engineering® guarantees flexibility, quality output and reliability. Production line automation allows companies to leverage resourcefulness and efficiency without sacrificing quality.

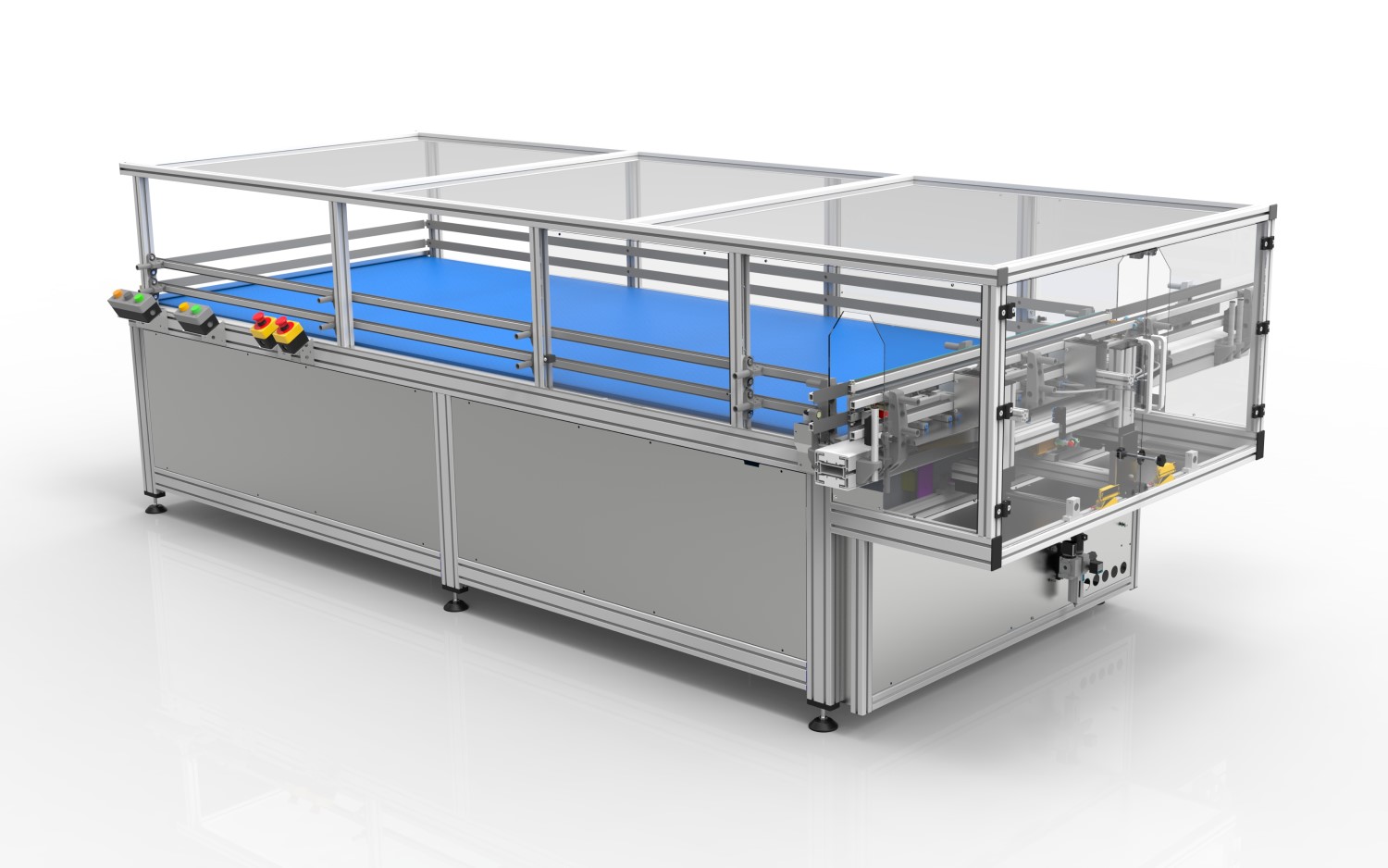

Autobagger System

The Autobagger System will reliably collate and bag products for transport. This system can be manufactured either as a stand-alone OEM product or fully-automated turnkey system as part of a larger production line.

KEY FEATURES OF THE AUTOBAGGER SYSTEM:

- Automatic bottle collating and bagging machine

- Uses continuous bags that can be custom made to length for each product

- Versatile conveyor in-feed options available

- Dual in-feed of 2 products simultaneously

- The system accommodates both half size and full-size bags simultaneously

- Servo controlled for maximum flexibility

- Automatic pallet in-feed system

- Integrated pallet de-stacker (optional)

- AGV load positions for pallets or layer boards

- System safety interlocked and guarded as per Australian and New Zealand Standards

Autobagger System MK3

Autobagger System MK5

Autobagger System (Video)

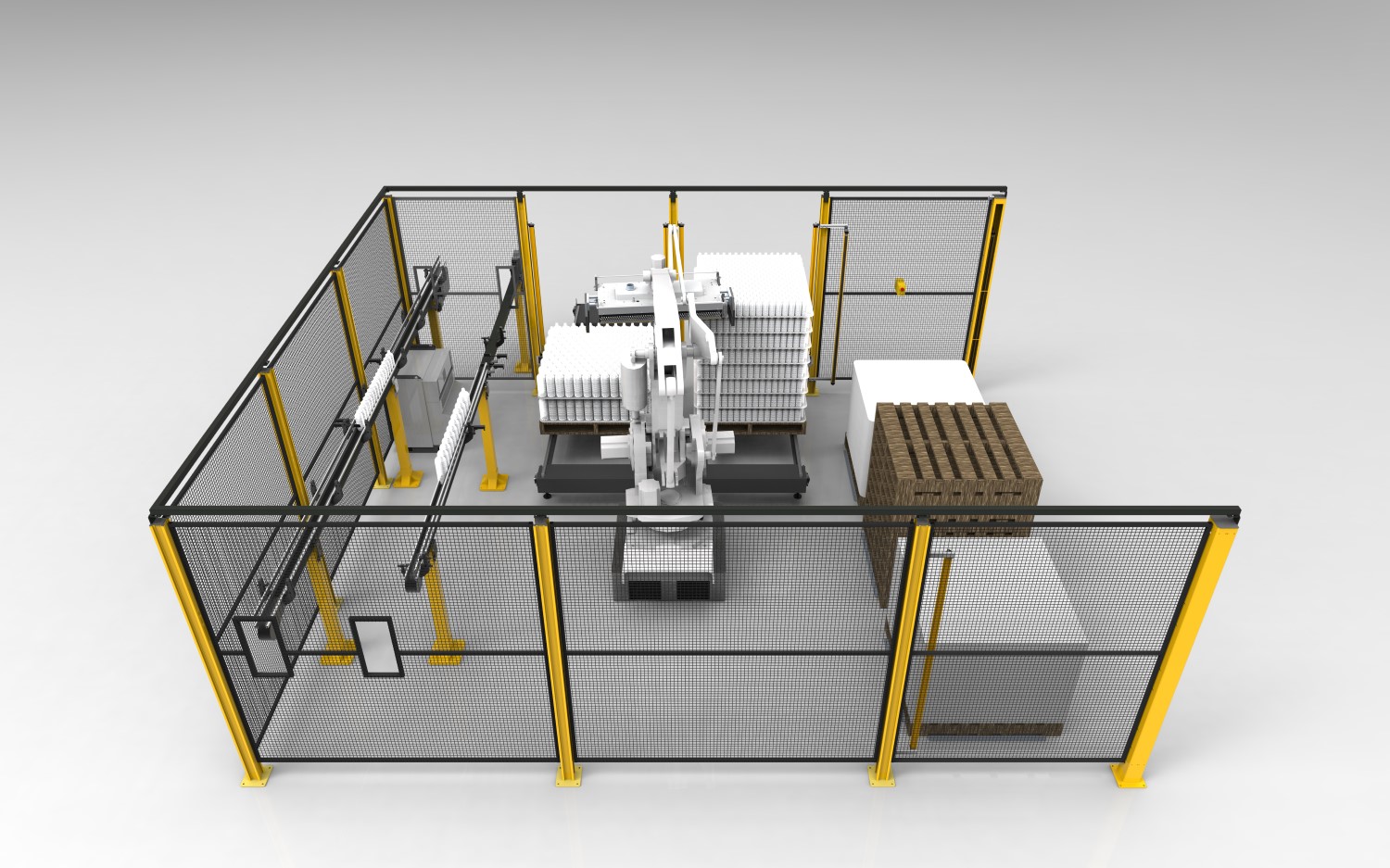

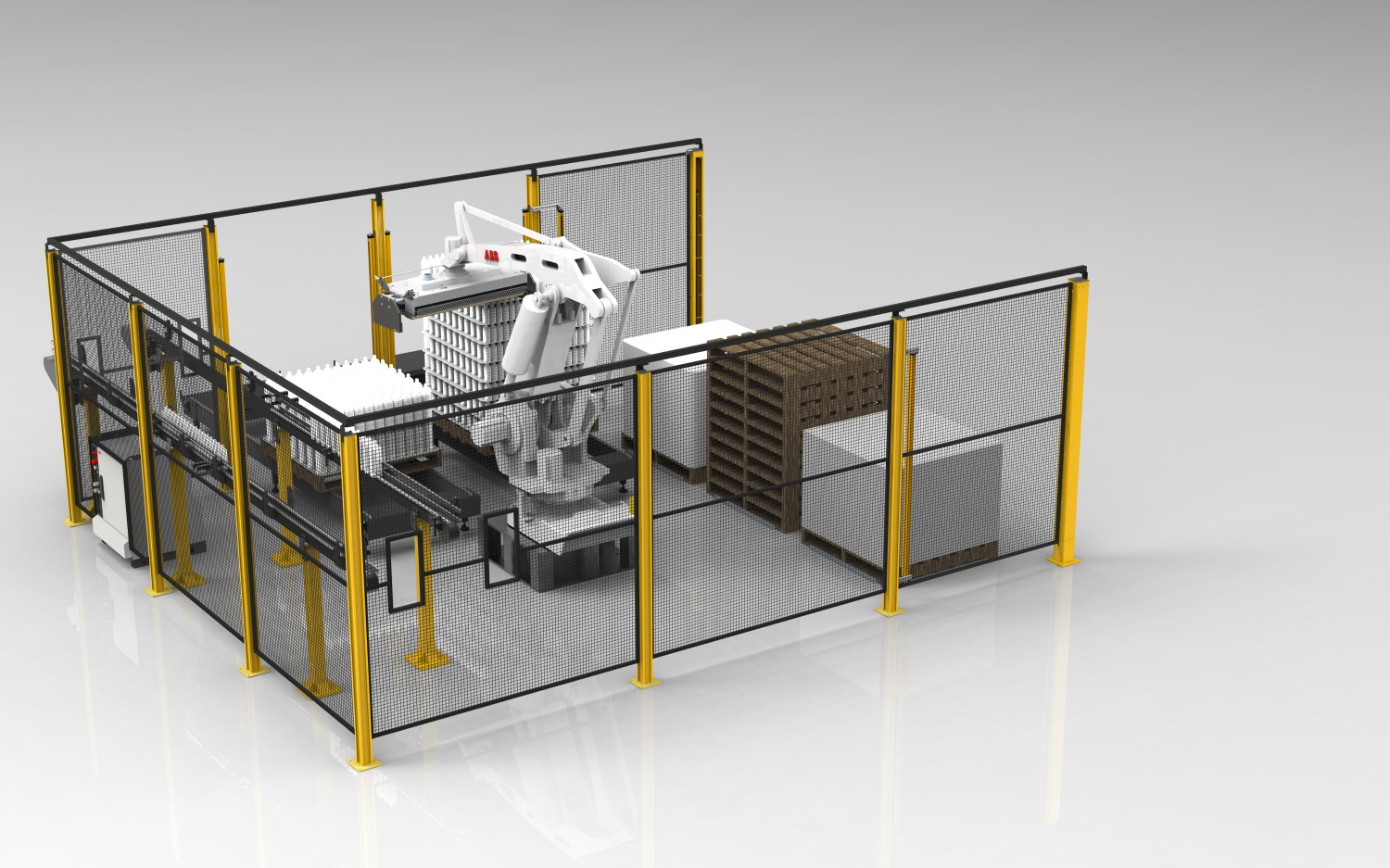

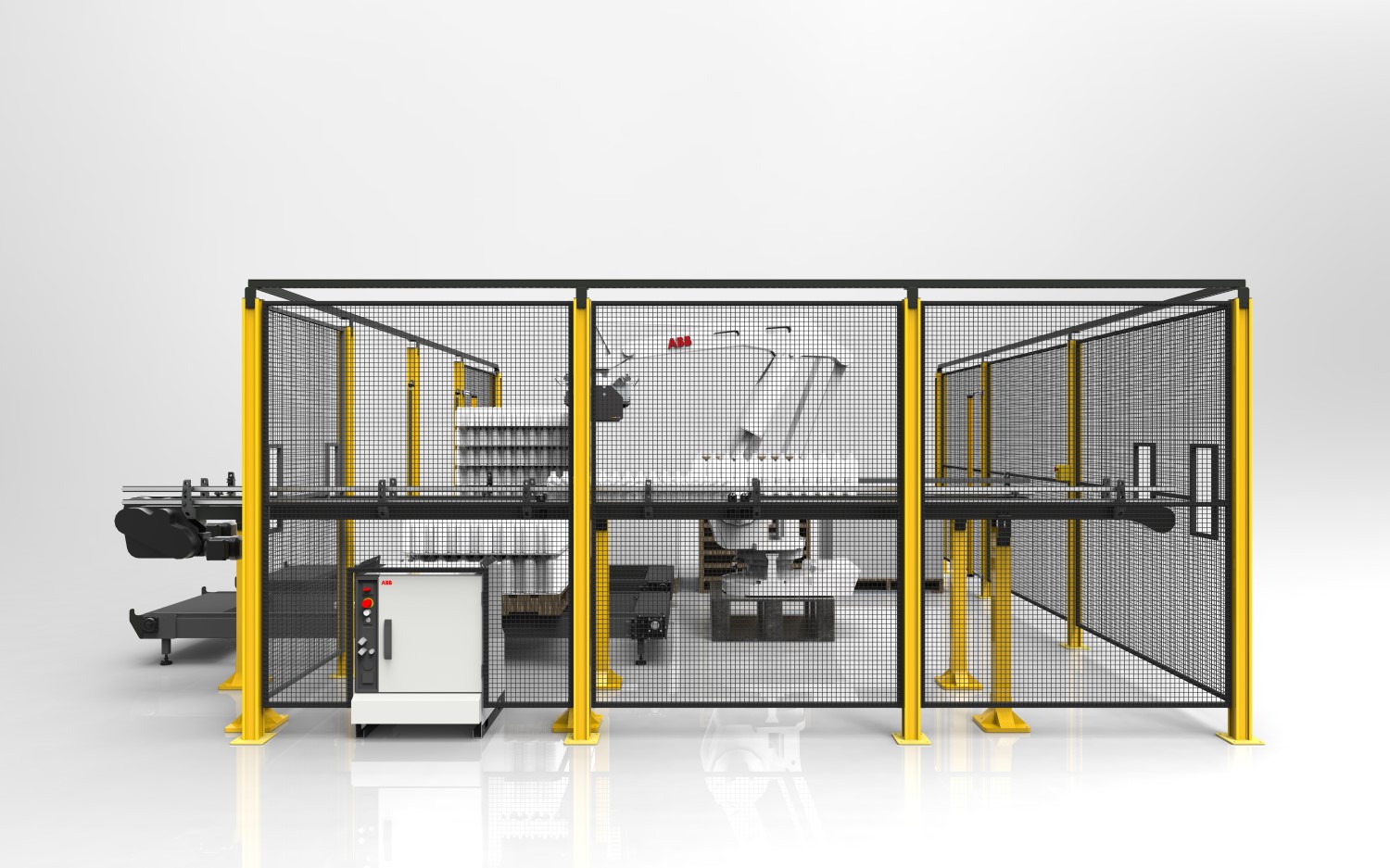

Bi-directional Palletiser and Depalletiser System

The Bi-directional Palletiser and Depalletiser System is designed with our universal bottle vacuum head to handle various bottles sizes. This versatility in combination with our pallet in-feed and out-feed system gives customers a versatile solution to suit many bottle lines.

KEY FEATURES OF THE BI-DIRECTIONAL PALLETISING AND DE-PALLETISING CUBE:

- Multifunctional bottle palletising and de-palletising system can perform various tasks on-demand as follows:

- De-palletise from pallet to conveyor

- Palletise from conveyor to pallet

- Use as a buffering system for inline blow moulding as the system will feed bottle as well as palletise bottles, as required

- Central control via HMI

- One ABB robot equipped with a Mexx Universal Bottle Vacuum Head

- Automatic multi-pallet in-feed and out-feed

- System safety interlocked and guarded as per Australian and New Zealand Standards

Bi-directional Palletising and Depalletising Cube

Bi-directional Palletising and Depalletising Cube (Video)

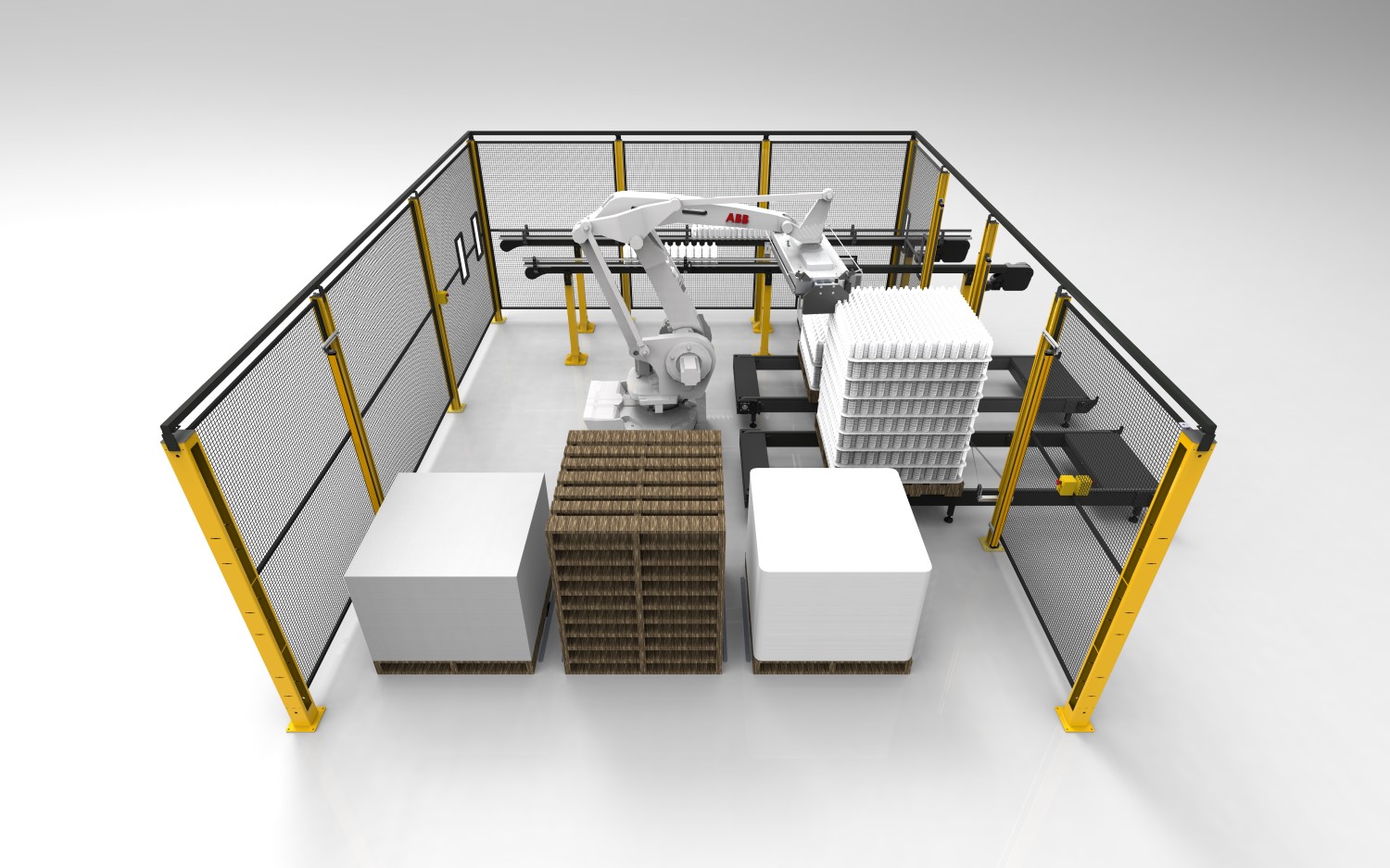

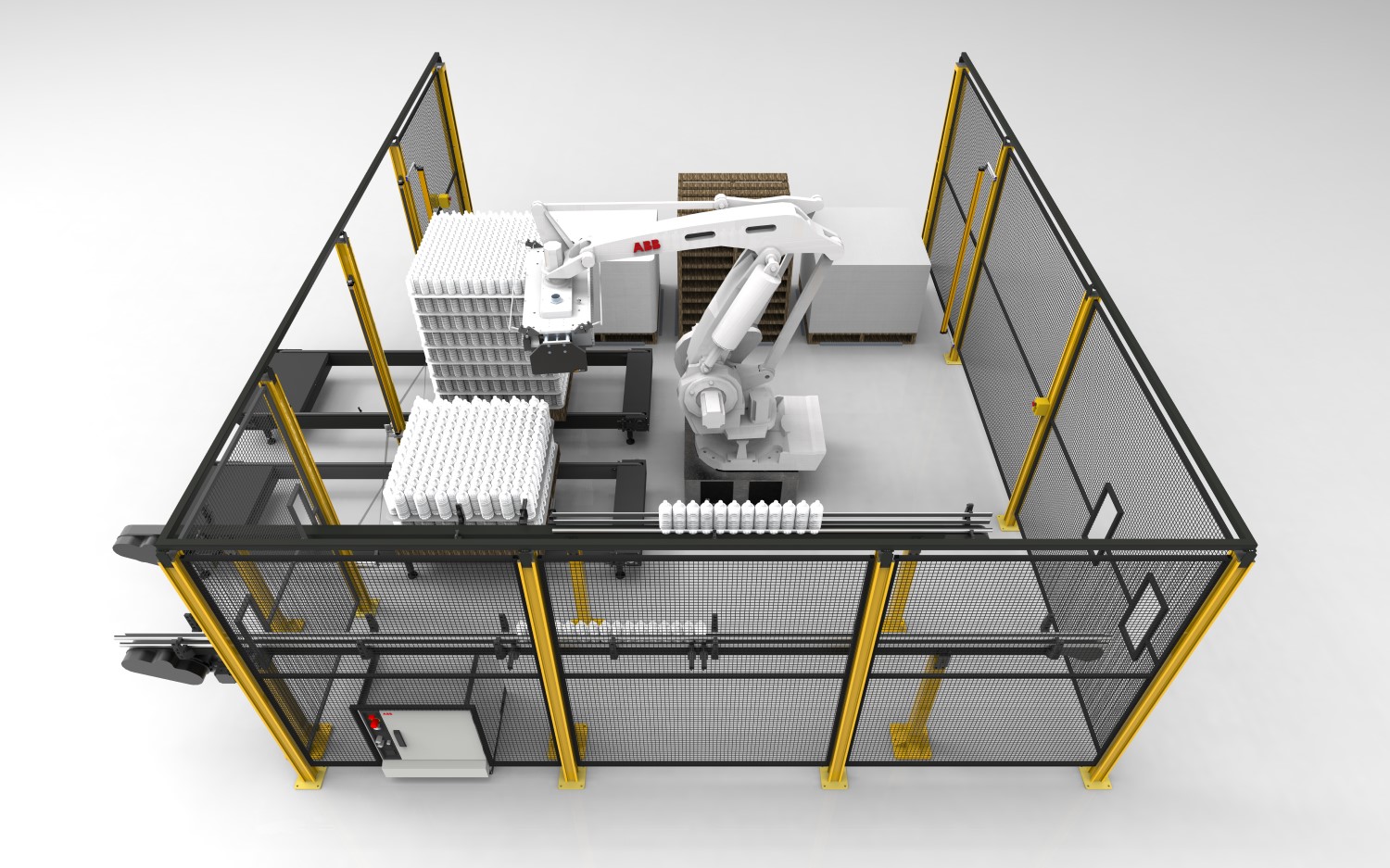

Bottle Palletiser System

The Bottle Palletiser System will pick and place bottles onto layers on a pallet. The system can have one robot picking up from 2 different conveyors and dropping off bottles onto two separate pallets.

KEY FEATURES OF THE BOTTLE PALLETISER SYSTEM:

- Seamless bottle palletising system

- Central control via HMI

- One ABB robot equip with a Mexx Universal Bottle Vacuum Head

- Automatic multi-pallet out-feed

- System safety interlocked and guarded as per Australian and New Zealand Standards

Bottle Palletiser System

Bottle Palletiser System (Slideshow)

Debagger System

The Debagger System will reliably unseal bagged products, pick and place them into a conveyor in preparation for further processing. This system can be manufactured either as a stand-alone OEM product or fully-automated turnkey system as part of a larger production line.

KEY FEATURES OF THE DEBAGGER SYSTEM:

- Bottles are automatically removed from the bag

- The system will accommodate full size & half size bag

- Automatic bag de-palletising

- Semi-Automatic version also available

- Bags are cut with precision without damaging any bottles

- Automatic bag collection and compression into a waste sock

Debagger System

Debagger System (Video)

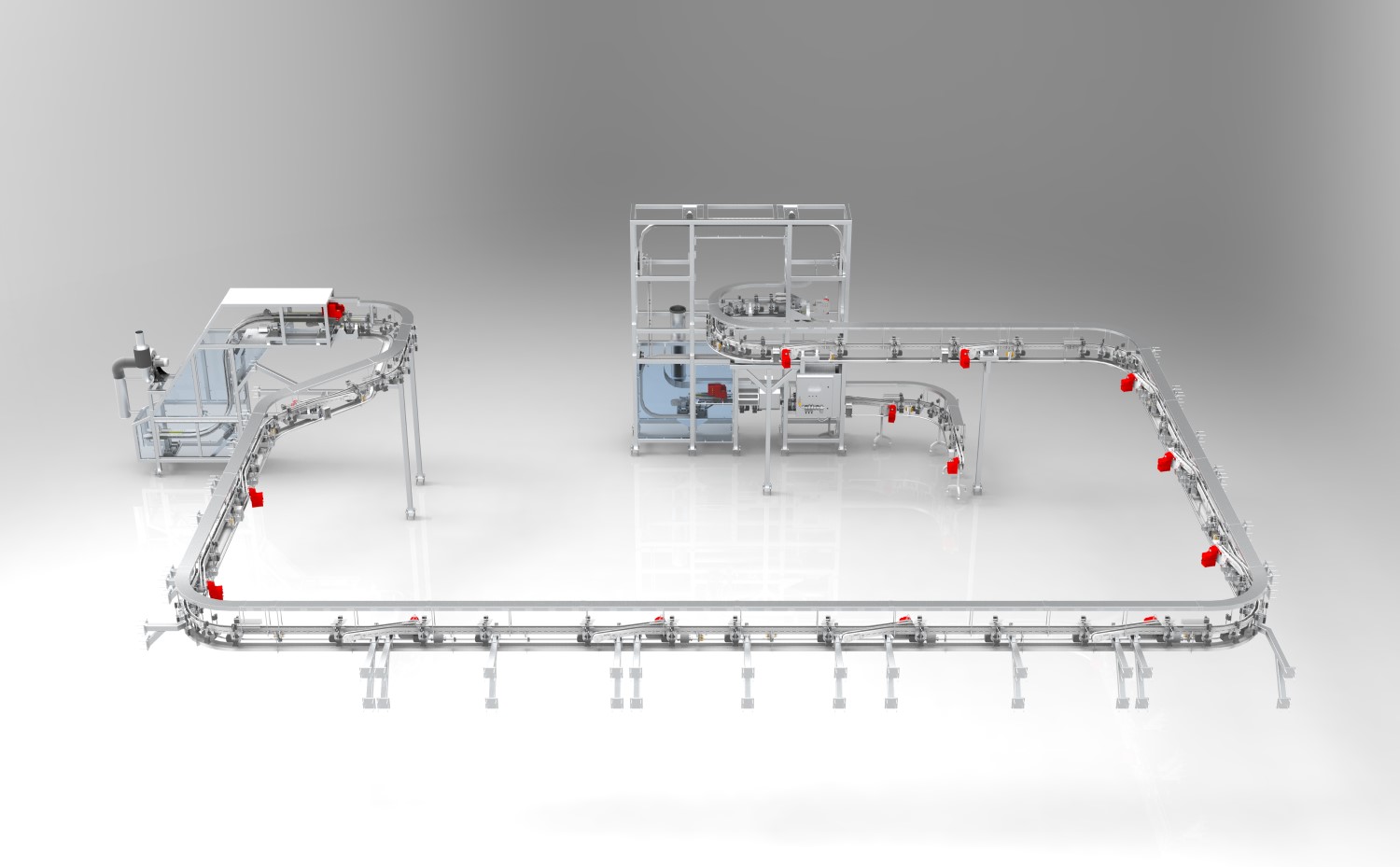

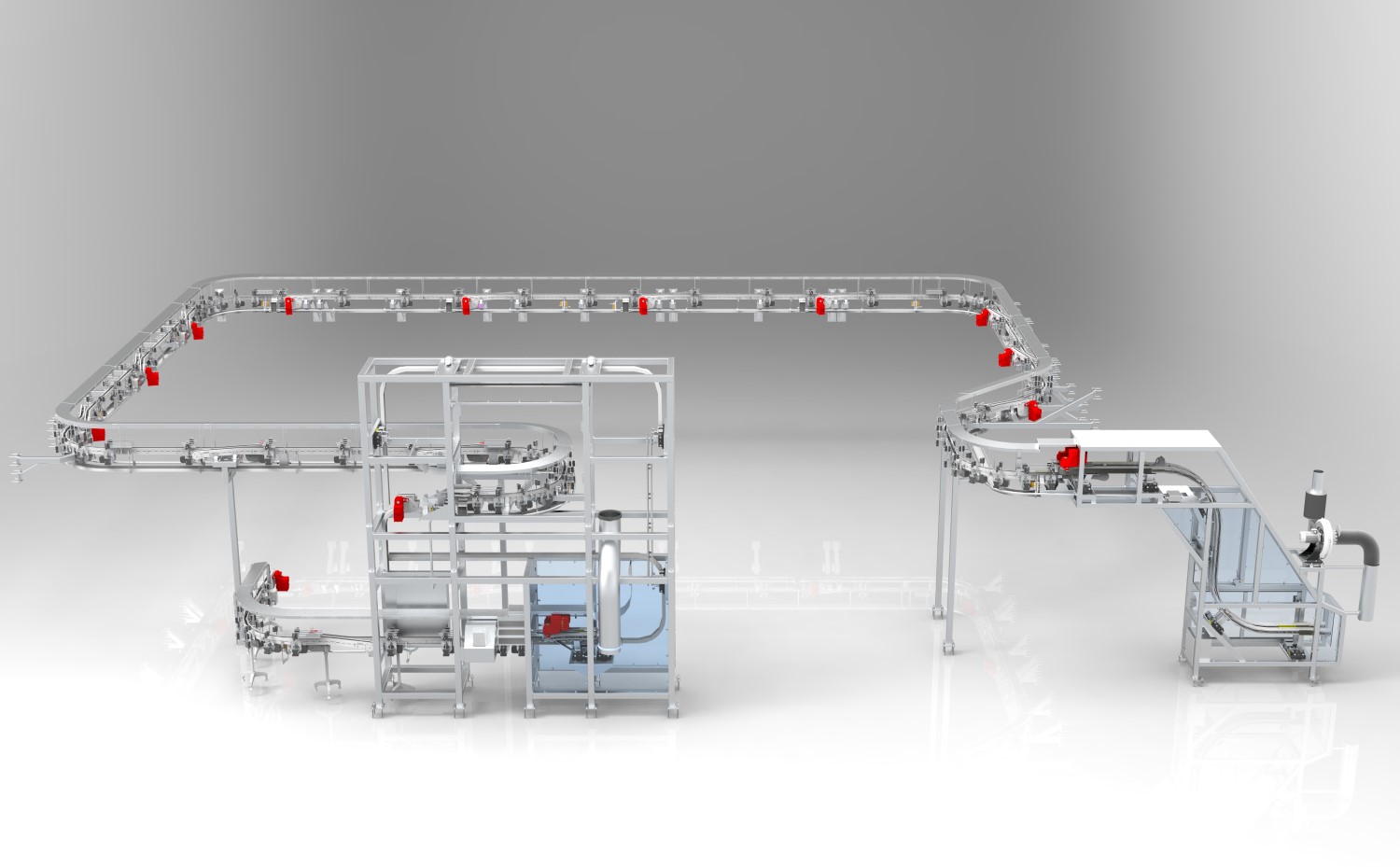

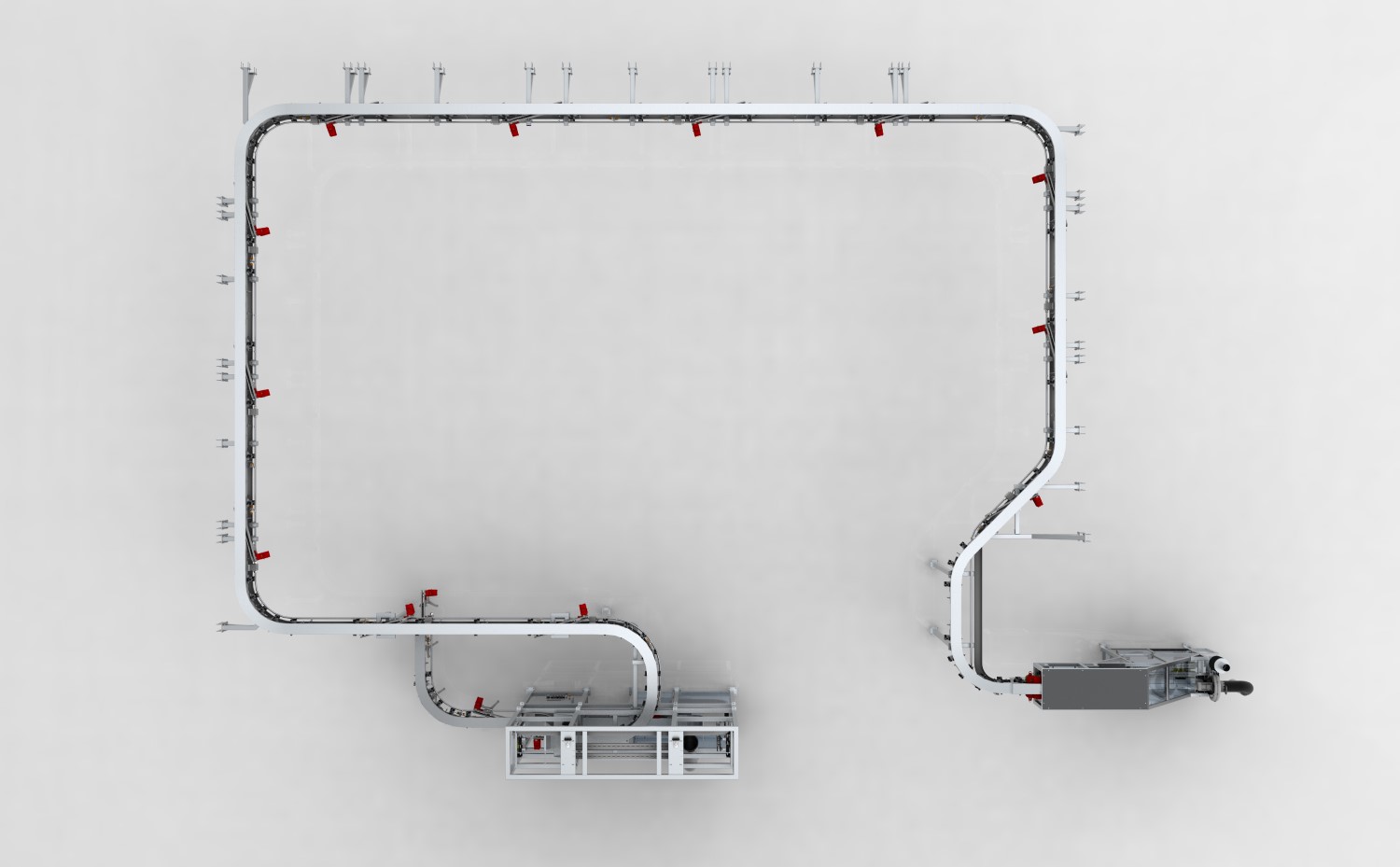

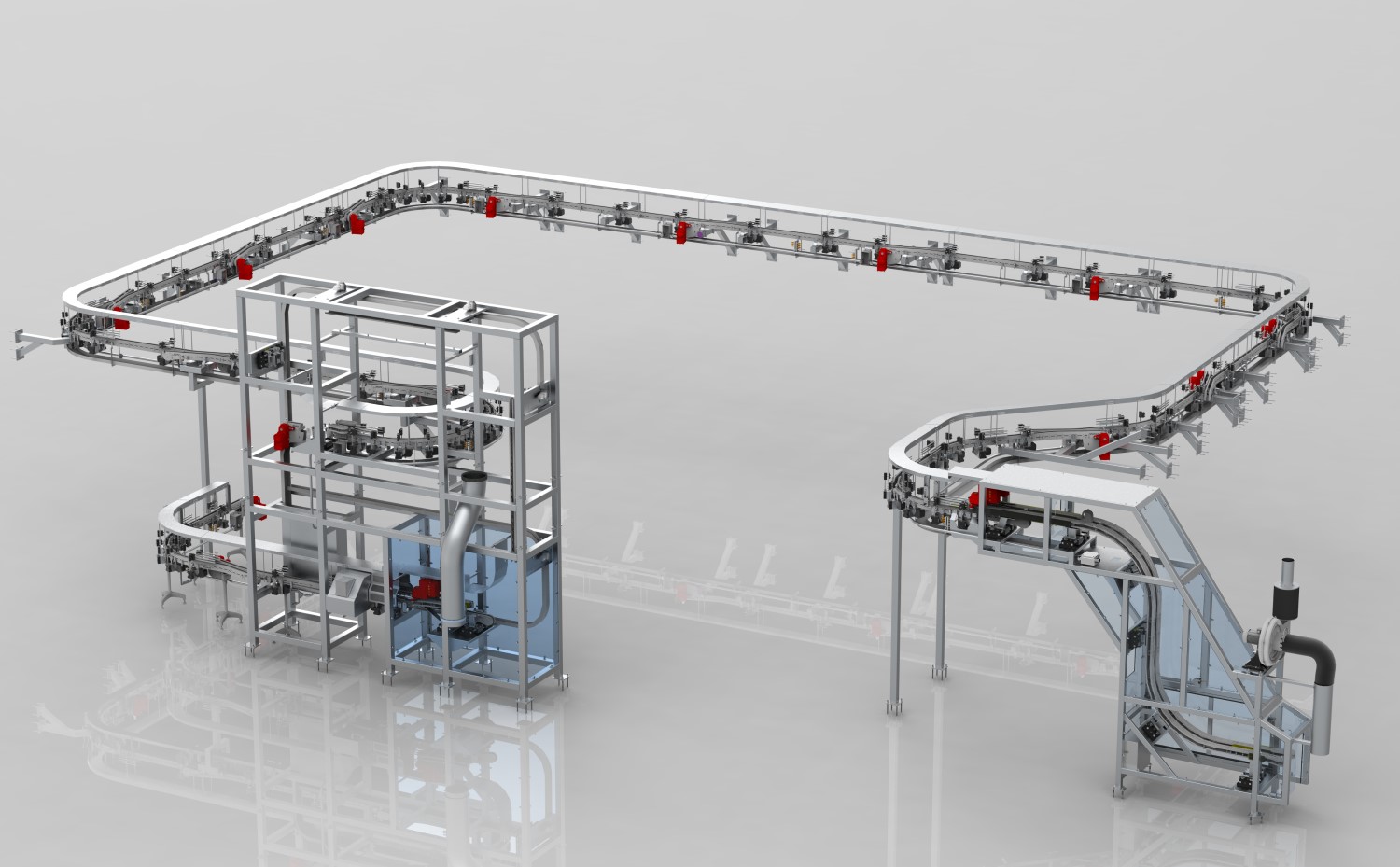

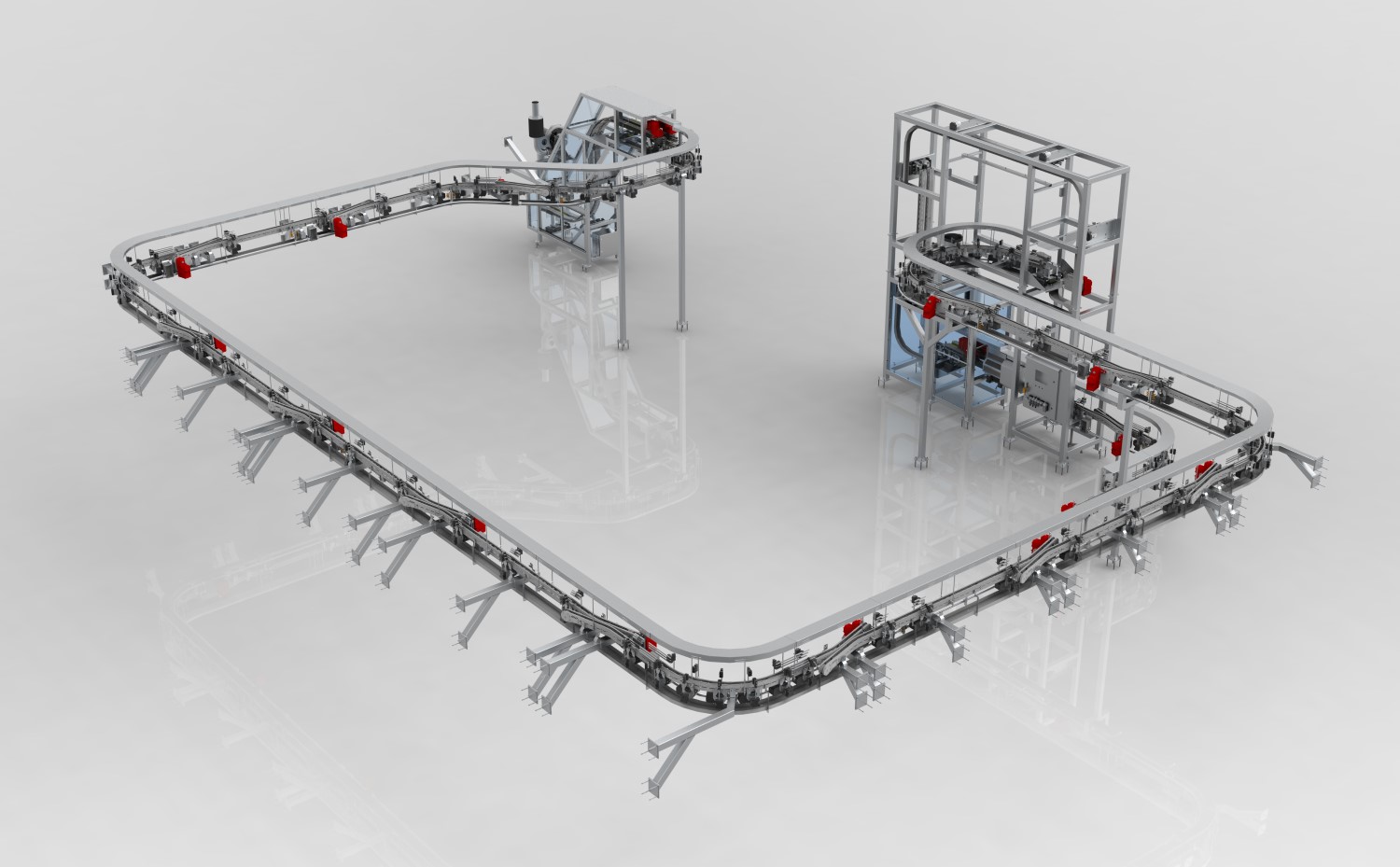

Conveyor System

The Conveyor System controls product delivery from point A to point B with the use of various conveyor chain materials. Its guide rail system is fully adjustable to ensure continuous movement of the bottle around a curve.

KEY FEATURES OF THE CONVEYOR SYSTEM:

- Aluminium or Stainless conveyor system

- Includes automatic self-centring guide rail adjusters

- Integrated transfers from upstream conveyors

- Integrated transfers to downstream conveyors

- High-speed with virtually no back-pressure and bottle gaps

- Accumulation system

- Full system control

- System safety interlocked and guarded as per Australian and New Zealand Standards

Conveyor System

Conveyor System (Slideshow)

Conveyor System (Video)

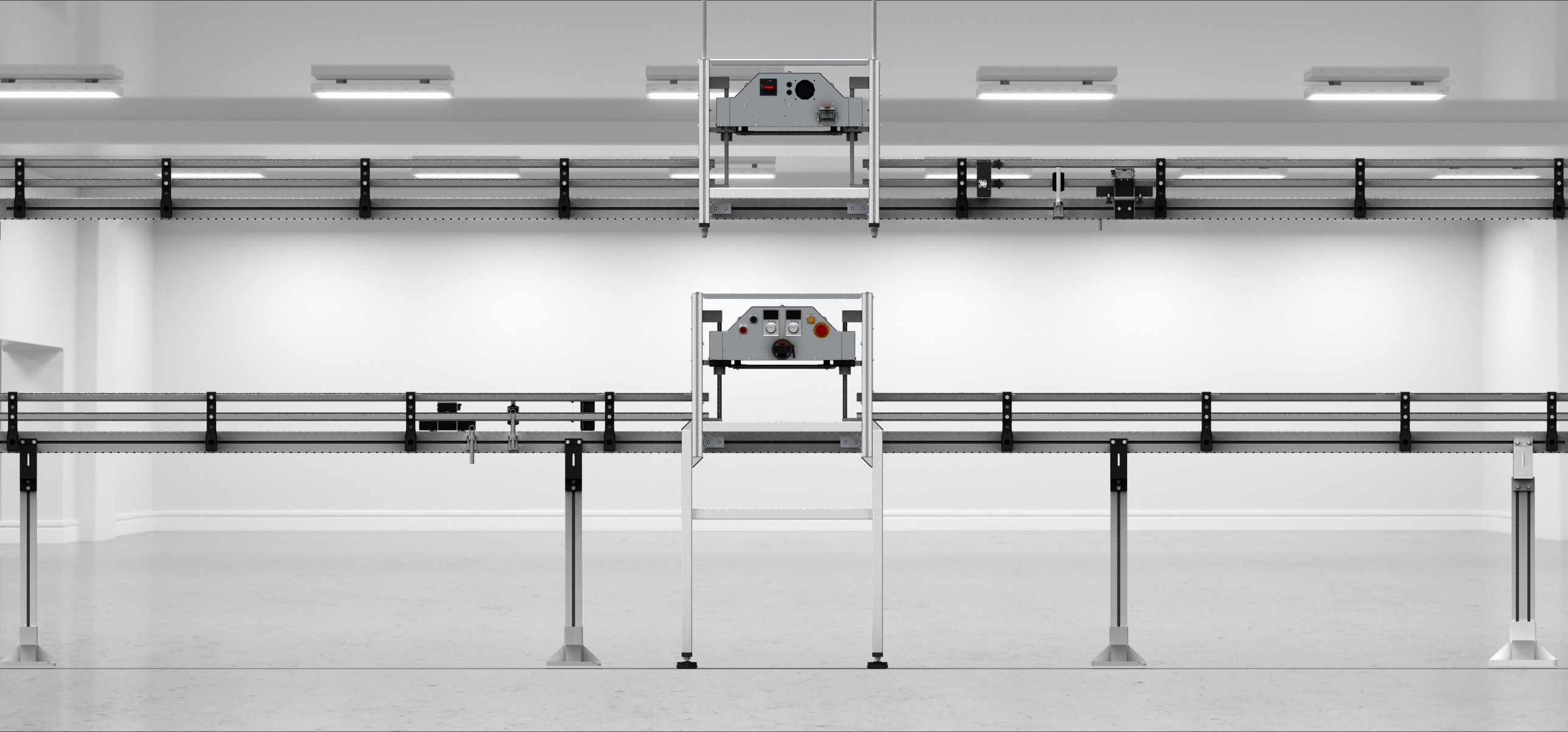

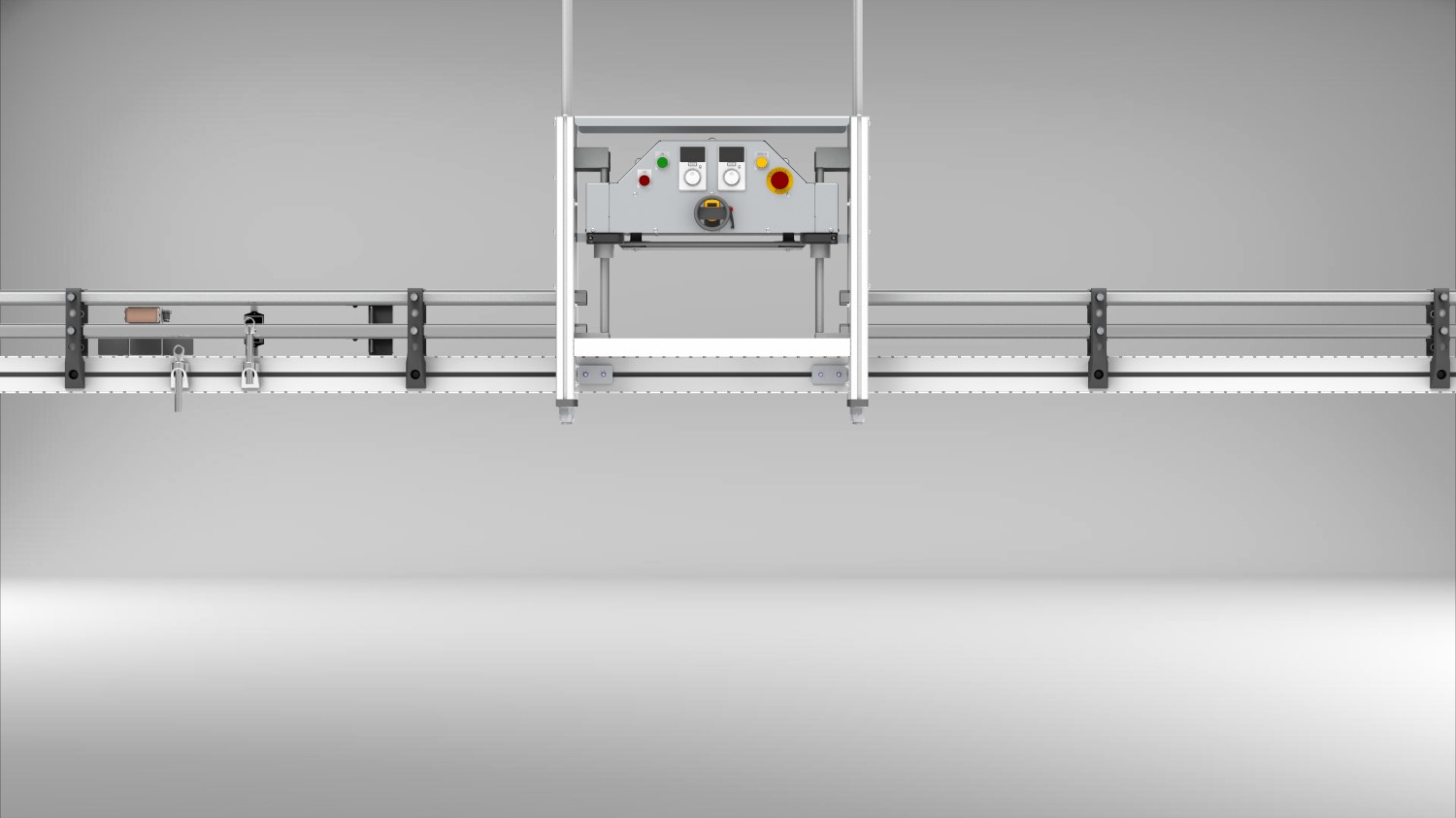

Continuous Bottle Turner

The continuous bottle turner is designed to reorient bottles on a conveyor line. The bottles are turned by independently adjusting the speeds of the two belts with respect to the conveyor speed. The system can either be mounted on the floor or in the ceiling as an overhead version.

KEY FEATURES OF THE CONTINUOUS BOTTLE TURNER:

- Two mounting options available (floor standing or roof hanging)

- The roof hanging kit includes a wired remote control pendant

- The remote control is available separately for floor standing models

- Both mounting options connect to the same base device, so changing the mounting method in the future is as easy as purchasing the appropriate mounting kit

- System safety interlocked and guarded as per Australian and New Zealand Standards

Continuous Bottle Turner (Ceiling Mounted and Floor Mounted)

Continuous Bottle Turner (Ceiling Mounted)

Continuos Bottle Turner (Floor Mounted)

Vision System

The Vision System checks the orientation and quality of a product. It inspects the product for damage and determines how to handle it. A dedicated feeding system that automatically spaces the bottles can be added as an option.

KEY FEATURES OF THE VISION SYSTEM:

- 5” touch screen for operation and production information

- 20” Display and roller trackball for camera system control and setup

- Light tower for status indication

- Eject bottles using air blast

- PLC Controlled - Independent floor mounted frame for stability

- Central control via HMI

- System safety interlocked and guarded as per Australian and New Zealand Standards

Vision System (Video)

Vision System - Aluminium

Vision System - Stainless Steel

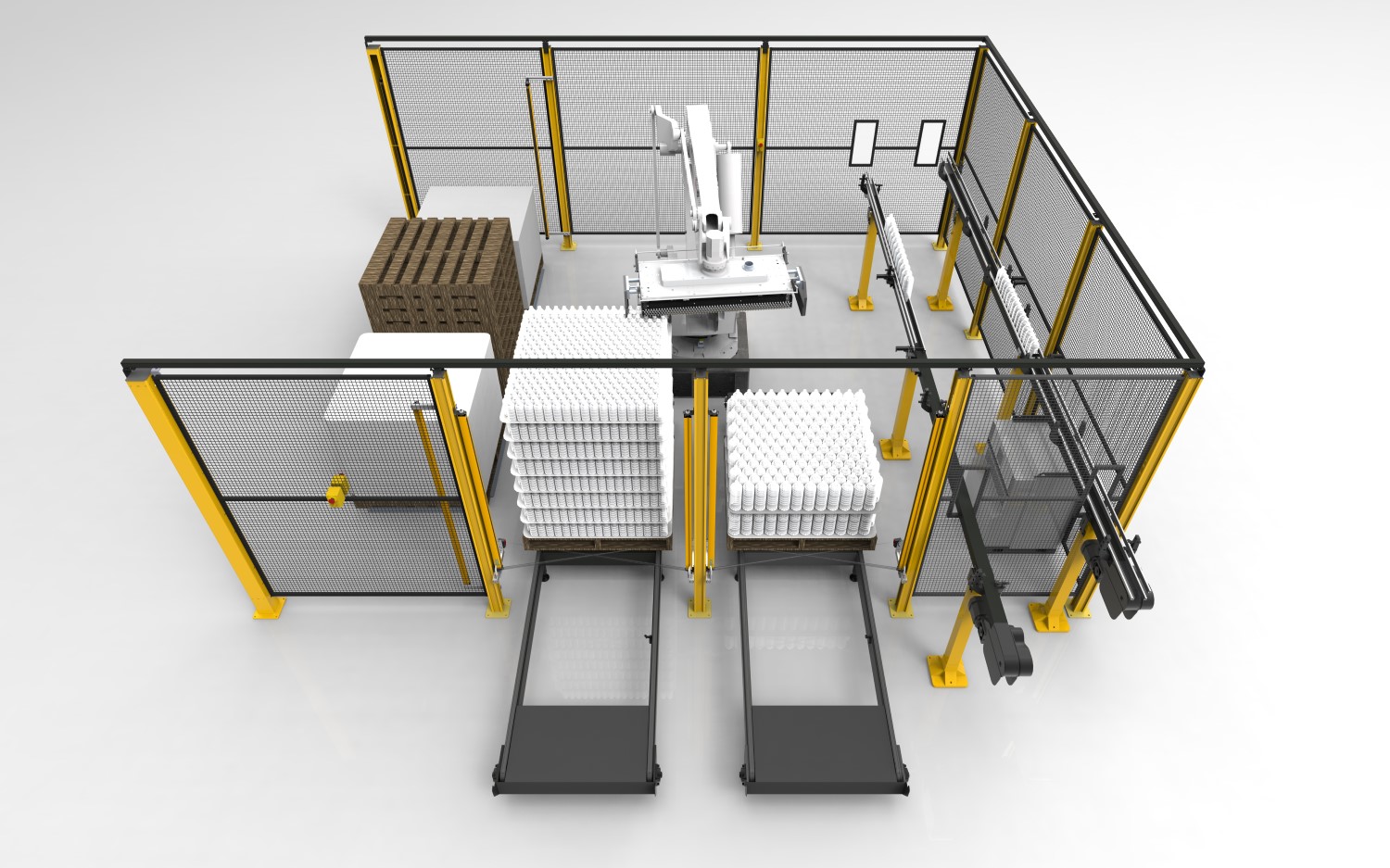

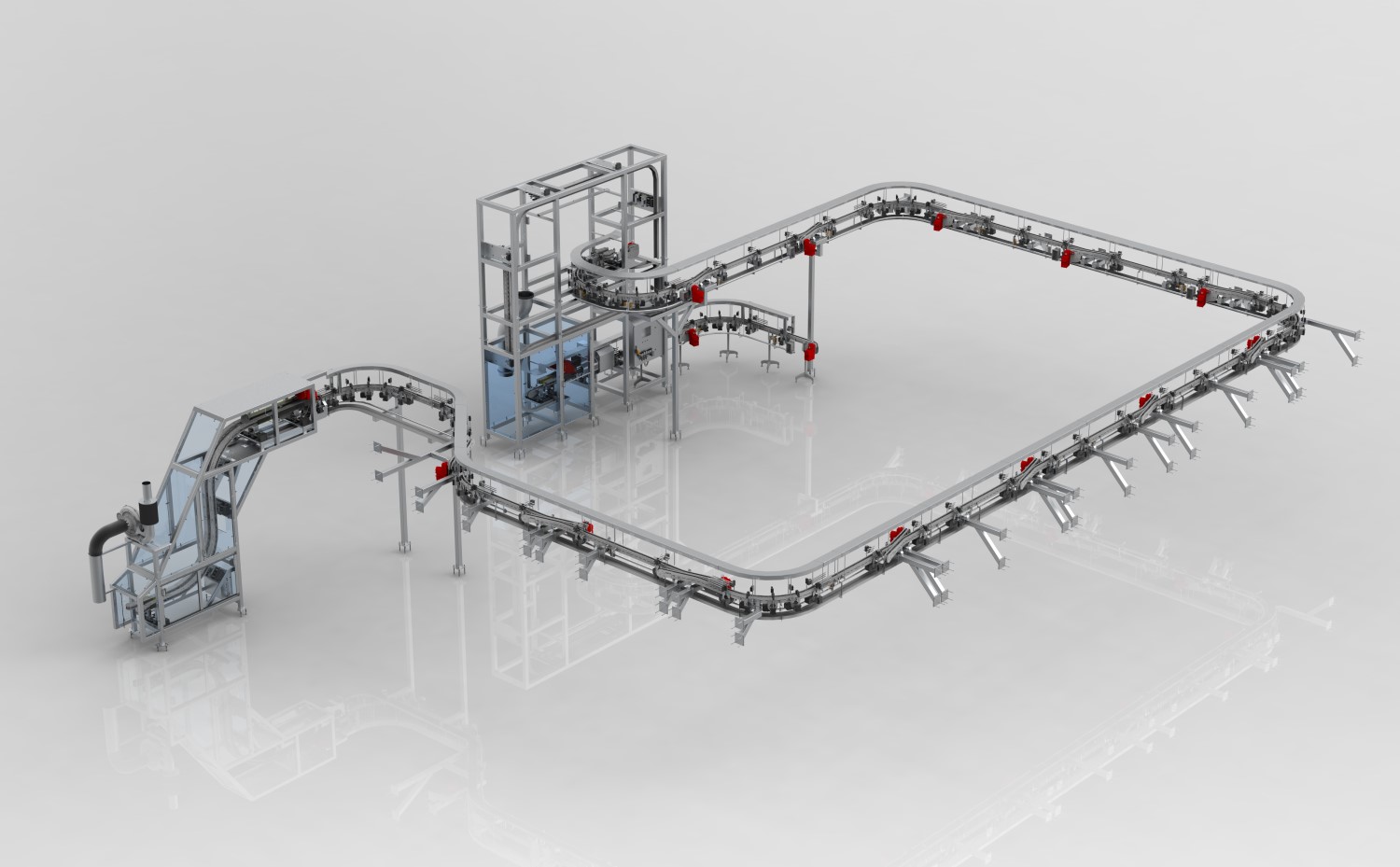

Custom Design & Automation

Palletising systems continue to develop up to this date. They are an essential part of automation, replacing human error and injury in manufacturing with efficiency and speed.

Palletisers can handle environments that would otherwise be hazardous and dangerous to workers. Instead of more labourers to do this work, many companies have adopted palletisers into their working environments to get the job done more quickly, effectively and safely.

Automated palletising gives manufactures continued advantages such as speed, error reduction, decreases in product damage and more accurate quality loading.

Packaging Machine (Concept Image)