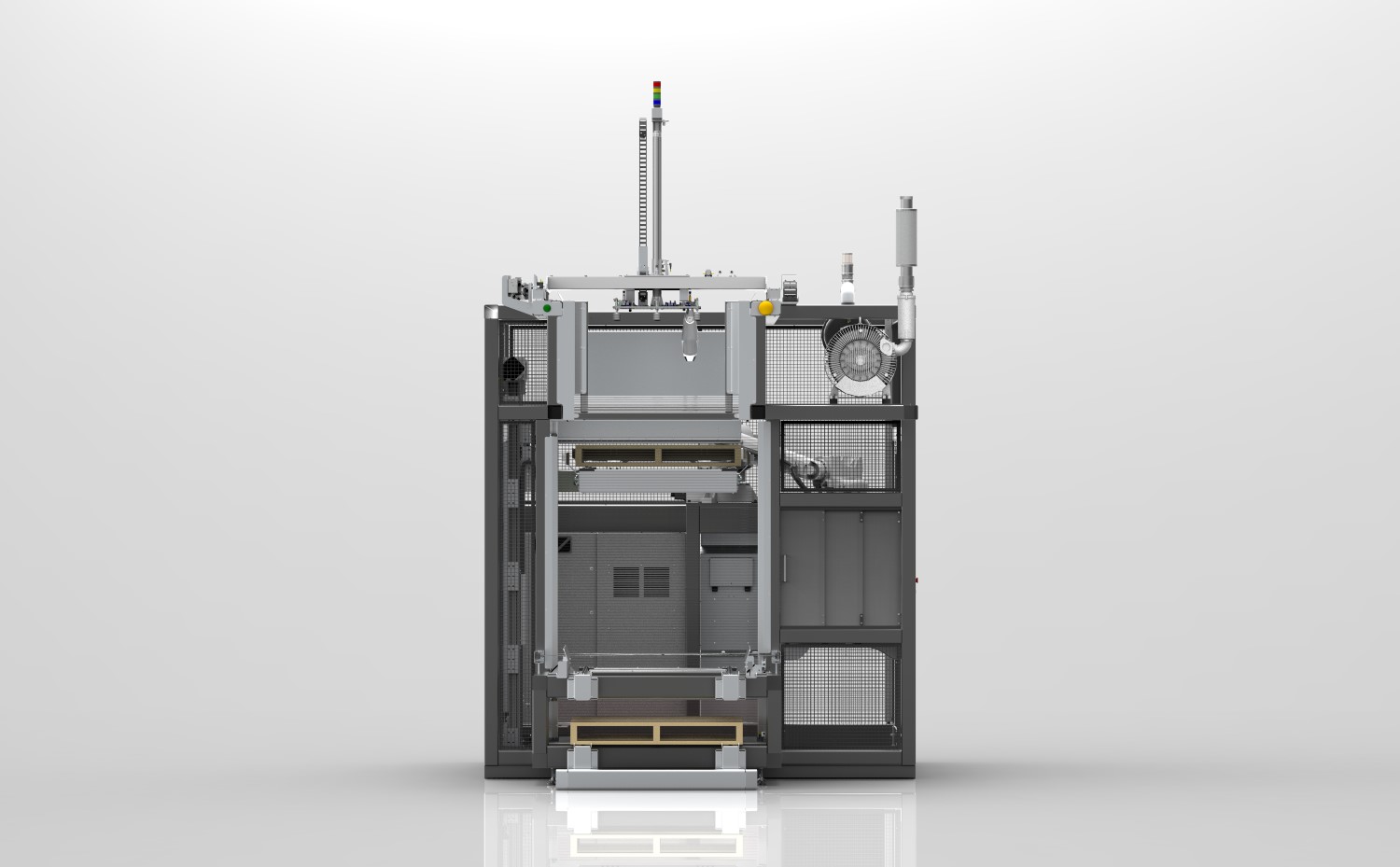

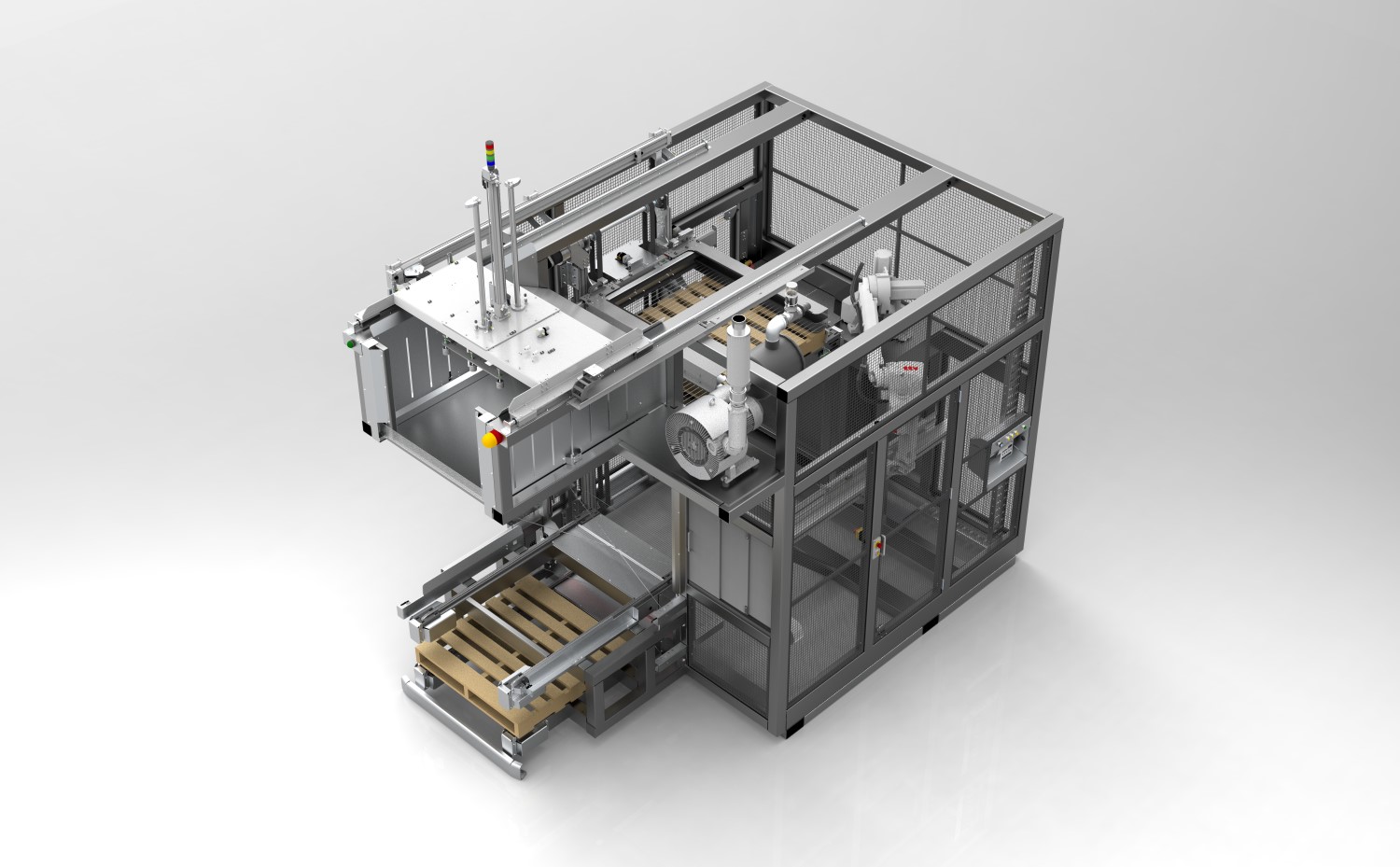

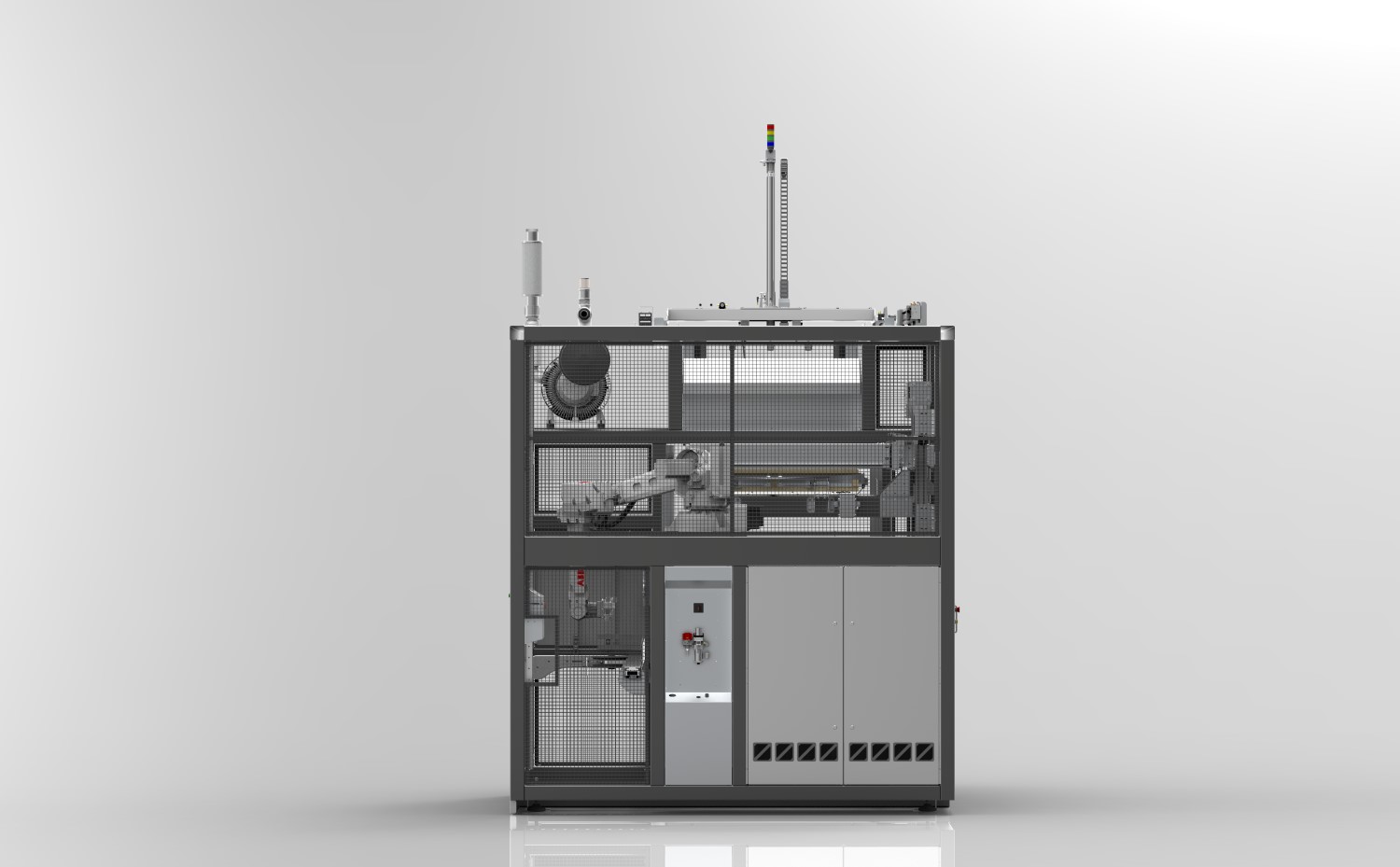

Bi-Directional Palletiser and Depalletiser System

The Bi-directional Palletiser and Depalletiser System is designed with our universal bottle vacuum head to

handle various bottles sizes. This versatility in combination with our pallet infeed and outfeed system

gives customers a versatile solution to suit many bottle lines.

This system can be manufactured either as a stand-alone OEM product or fully-automated turnkey system as part of a larger production line.

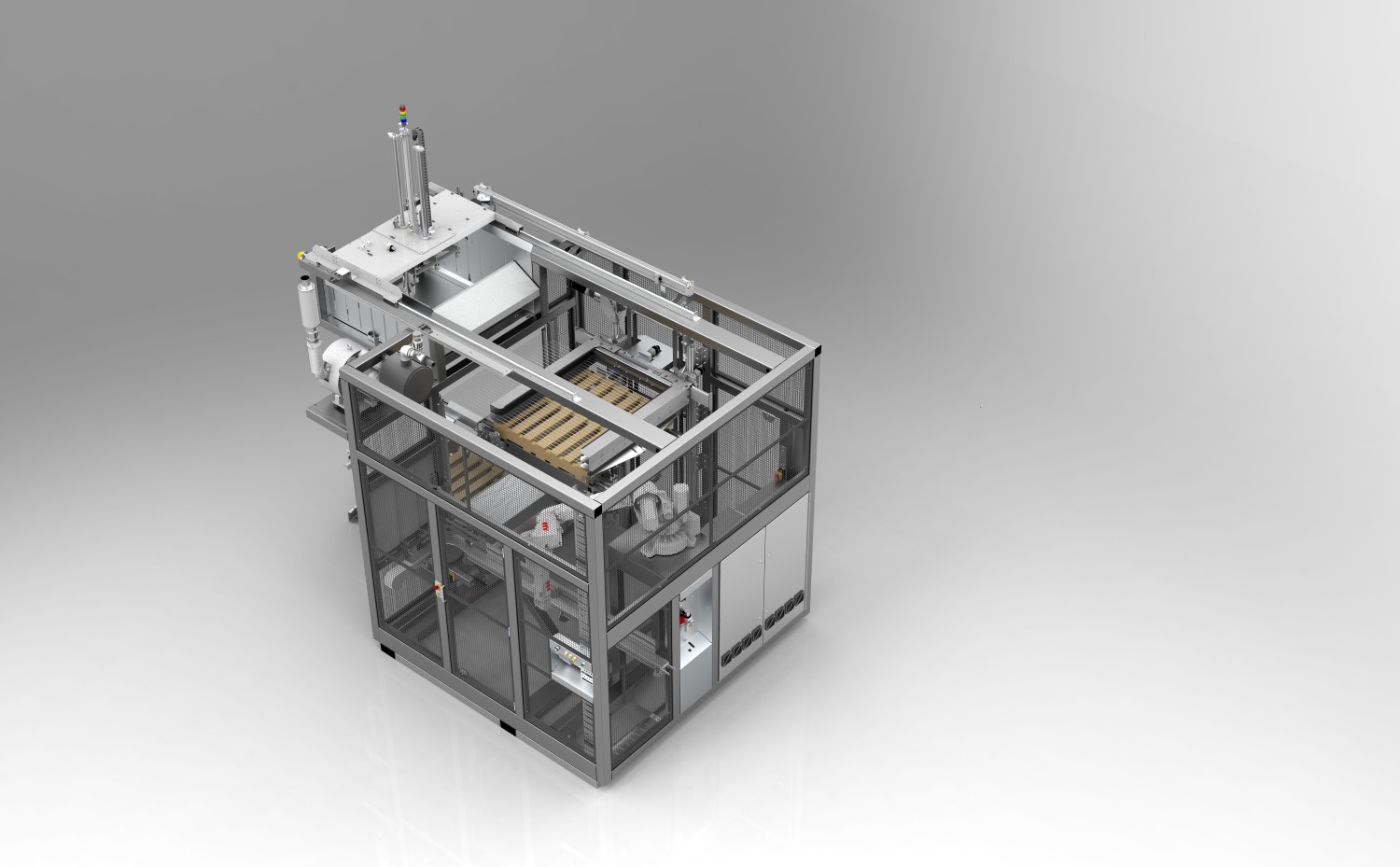

Bi-directional Palletising and Depalletising Cube

KEY FEATURES OF THE BI-DIRECTIONAL PALLETISING AND DEPALLETISING SYSTEM:

- Multifunctional bottle palletising and de-palletising system can perform various tasks on demand as follows:

|

- Central Control via HMI

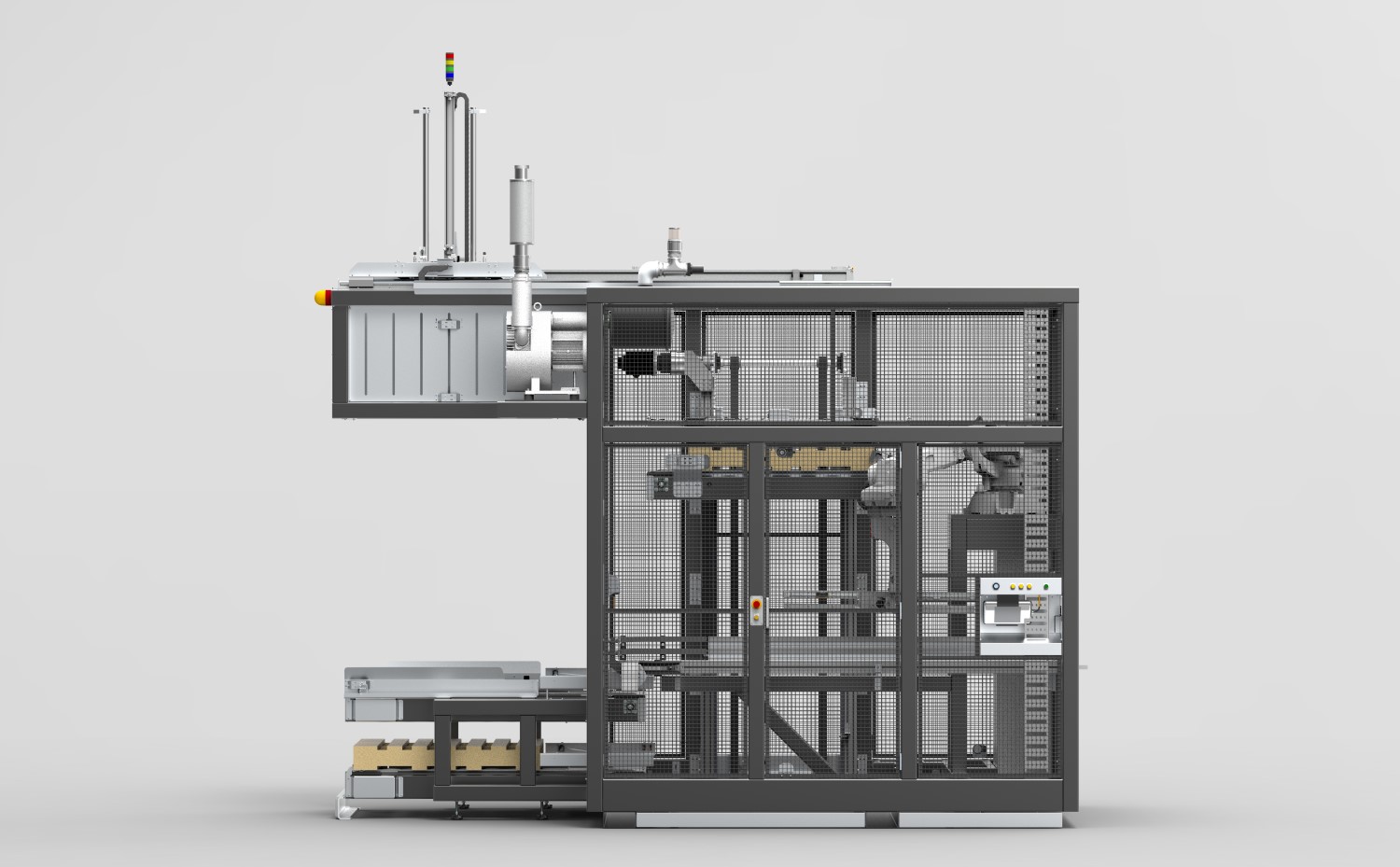

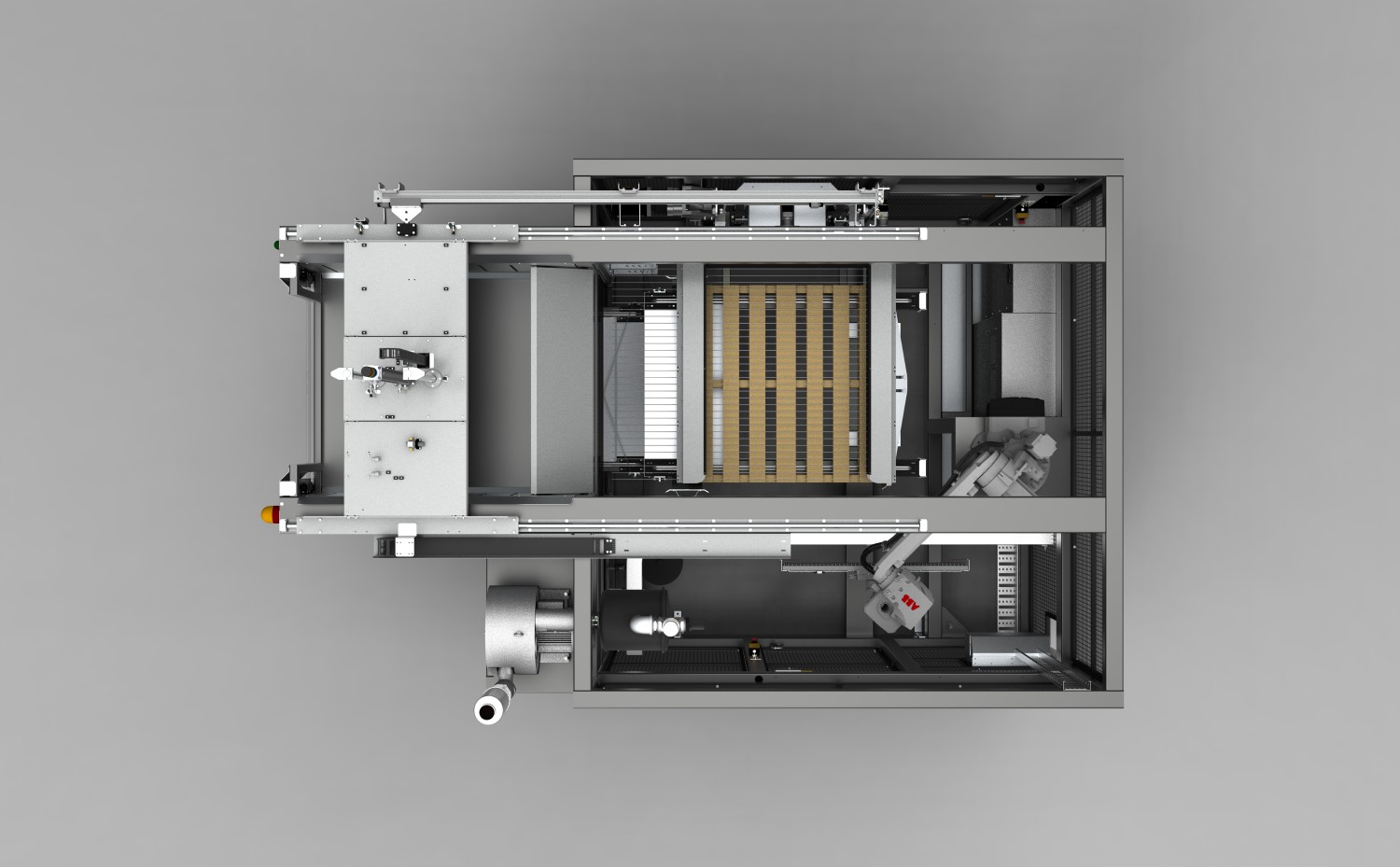

- One ABB robot equip with a Mexx Universal Bottle Vacuum Head

- Automatic multi-pallet infeed and outfeed

- System safety interlocked and guarded as per Australian and New Zealand Standards

HOW DOES IT WORK?

The Bi-directional Palletising and Depalletising Cube is programmable and highly versatile.

The process of palletising and depalletsing plastic bottles in a Bottling Plant starts from the blow moulding machine and ends at the palletising cube. The polyethylene terephthalate (PET) plastic are blown into shape. A conveyor will transport the plastic bottles to the Bi-directional Palletising Cube to carefully stack the loose bottles onto a pallet. The stacked bottles in a pallet is then indexed out to make way for the next pallet. Then, the process of palletising loose bottles starts again.

When a production line becomes congested, the accumulated products from a blow moulder can be diverted by either palletising or depalletising the finished product. The bi-directional functionality of this machine can act as accumulation buffer in a production line.

One of the best feature of this machine is its versatility. It is equipped with the Mexx Universal Bottle Vacuum Head. The vacuum head can handle large array of suction cups. It allows the ABB robot to pick up any bottle shape or size without any tool change.

The machine can handle various bottle shapes and sizes. The vacuum head can pick up PET (polyethylene terephthalate) bottles or ACP (Accredited Contract Packager) bottles. There is no need to change vacuum heads. It will adjust to suit any bottle. From a small plastic with 120ml high x 40ml width all the way up to 340ml high x 150ml width. The Mexx Universal Vacuum Head enables a robot to pick up square shaped and round bottles using a large array of suction cups and manifold pressure. The manifold pressure is consistent. It can pick up 10 pf 1.2 long bottles at the same time.

The Bi-directional Palletising and Depalletising Cube can also designed with industry 4.0 in mind. It's equipped to handle automatic guided vehicle or AGV. An AGV is a mobile robot that follows markers or wires in the floor or uses vision or lasers. They are often used in industry 4.0 to move stacks of bagged products or stack of layer pads around a manufacturing facility.

APPLICATIONS FOR THE BI-DIRECTIONAL PALLETISING AND DEPALLETISING SYSTEM:

The integration of high-end bi-directional palletising and depalletising system can increase productivity or efficiency within the following industries:

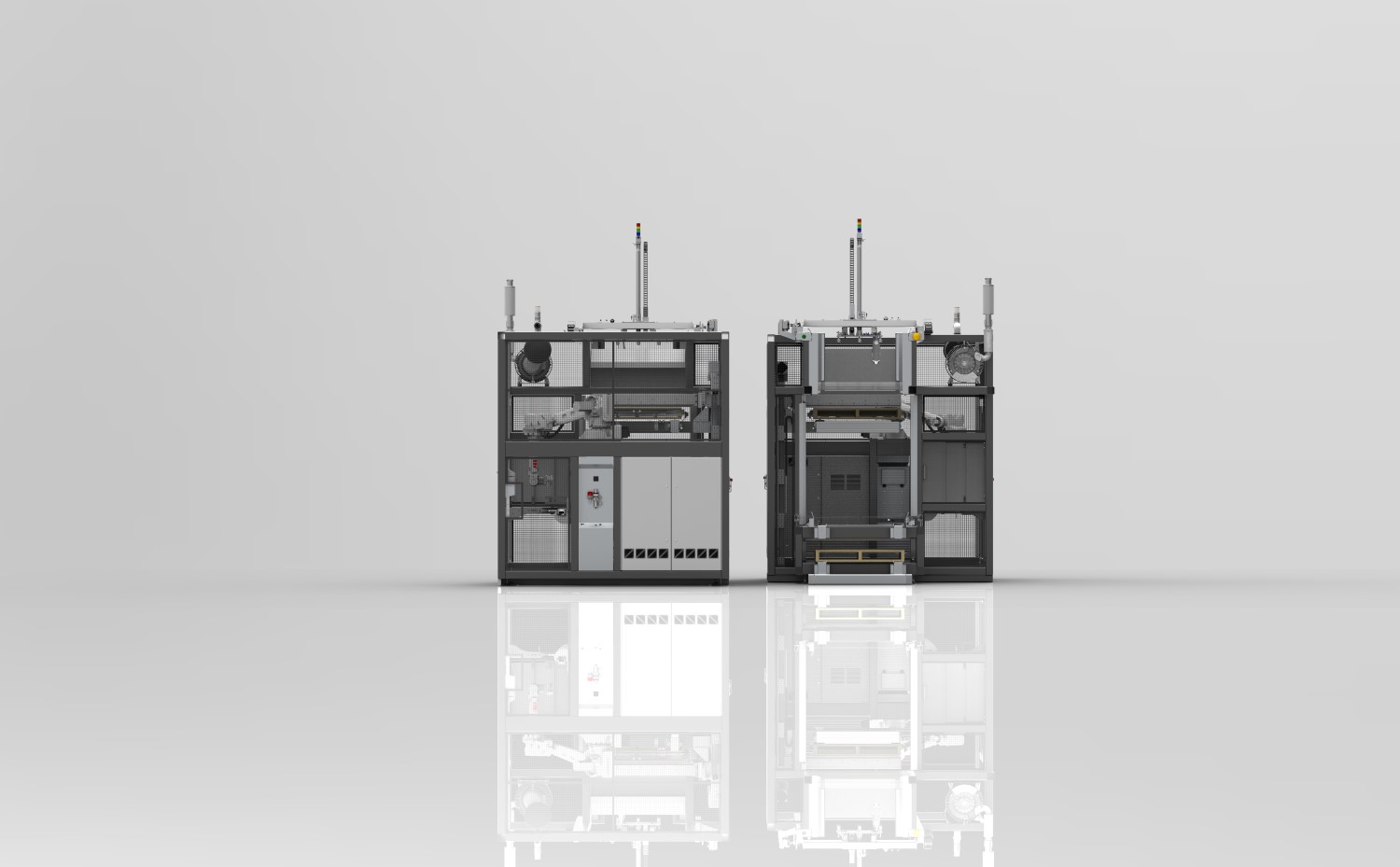

STAND-ALONE MACHINE

As a stand-alone EOM machine, the Bi-directional Palettsing and Depalletising Cube can be built to suit an existing autobagging and conveyor system.

The machine is about 3m x 3m x 3m high and weighs about 3 tones.

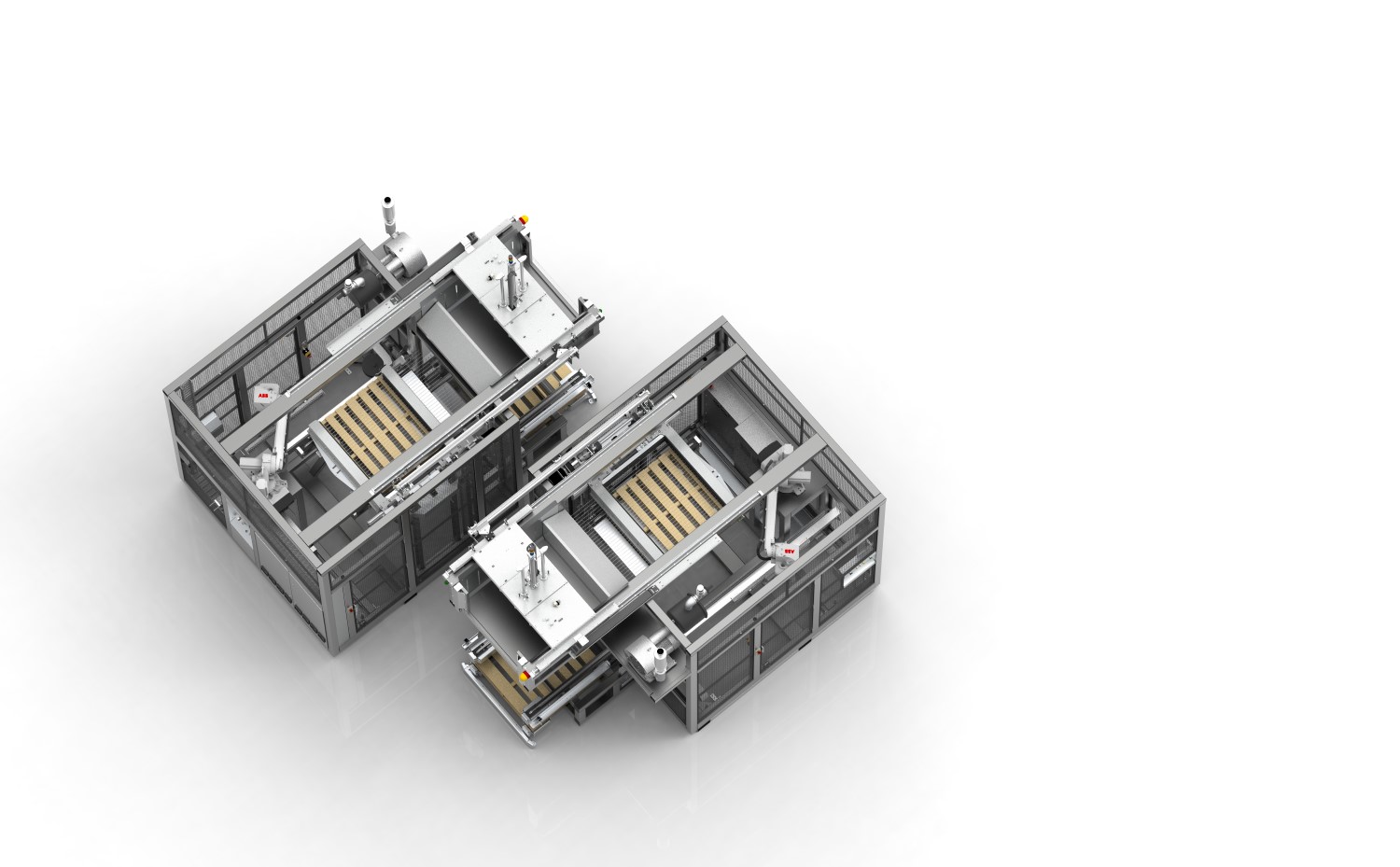

TURNKEY SYSTEM

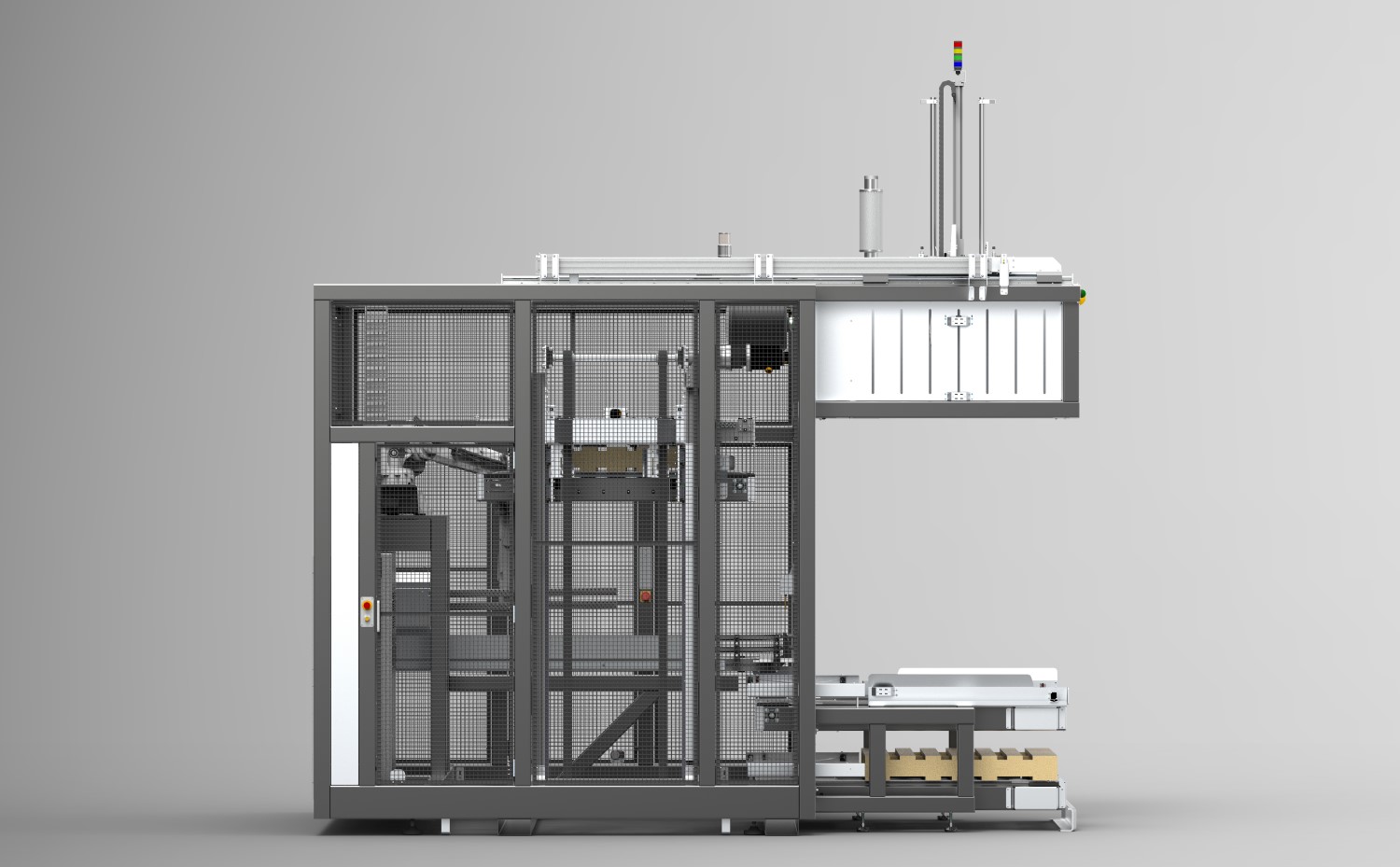

This type of setup will require a vision system to detect the bottle size and a conveyor system that will transport the bottles from the Bi-Directional Palletising and Depalletising Cube to the next production line. This setup is called a turnkey system.

As a turnkey system, the Bi-Directional Palletising and Depalletising Cube is a fully automated system where the following components are purposely added to create a sophisticated machine:

- Autobagger system

- Bottle palletiser system

- Debagger system

- Conveyor system

- Continuous bottle turner

- Vision system

DESIGN AND BUILD PERIOD

As a stand-alone machine or EOM product, it may take around 25-weeks from purchase order to delivery. On the other hand, a custom-made turnkey system can take longer depending on the customer's requests and specifications.

SERVICE MAINTENACE

Service maintenance is any work necessary to keep all customer facilities in good repair and operating condition. It includes maintaining and repairing essential components of a machine. This excludes explicitly new work and alterations such as:

- manufacturing and modifying machines and complete lines

- providing decorative treatments

- modifying vision systems

- attaching or extending items to the machine.

WARRANTY

All of Mexx Engineering® machines and turnkey systems come with a minimum of one year warranty on workmanship and materials.

Each system developed by Mexx Engineering® is a seamless automated machine that minimises environmental impact and maximises performance while ensuring the safety of its operator.

For more information, please contact 07 5571 5733 and choose option 1 for sales, to discuss the best combination of equipment and system maintenance to suit your application.