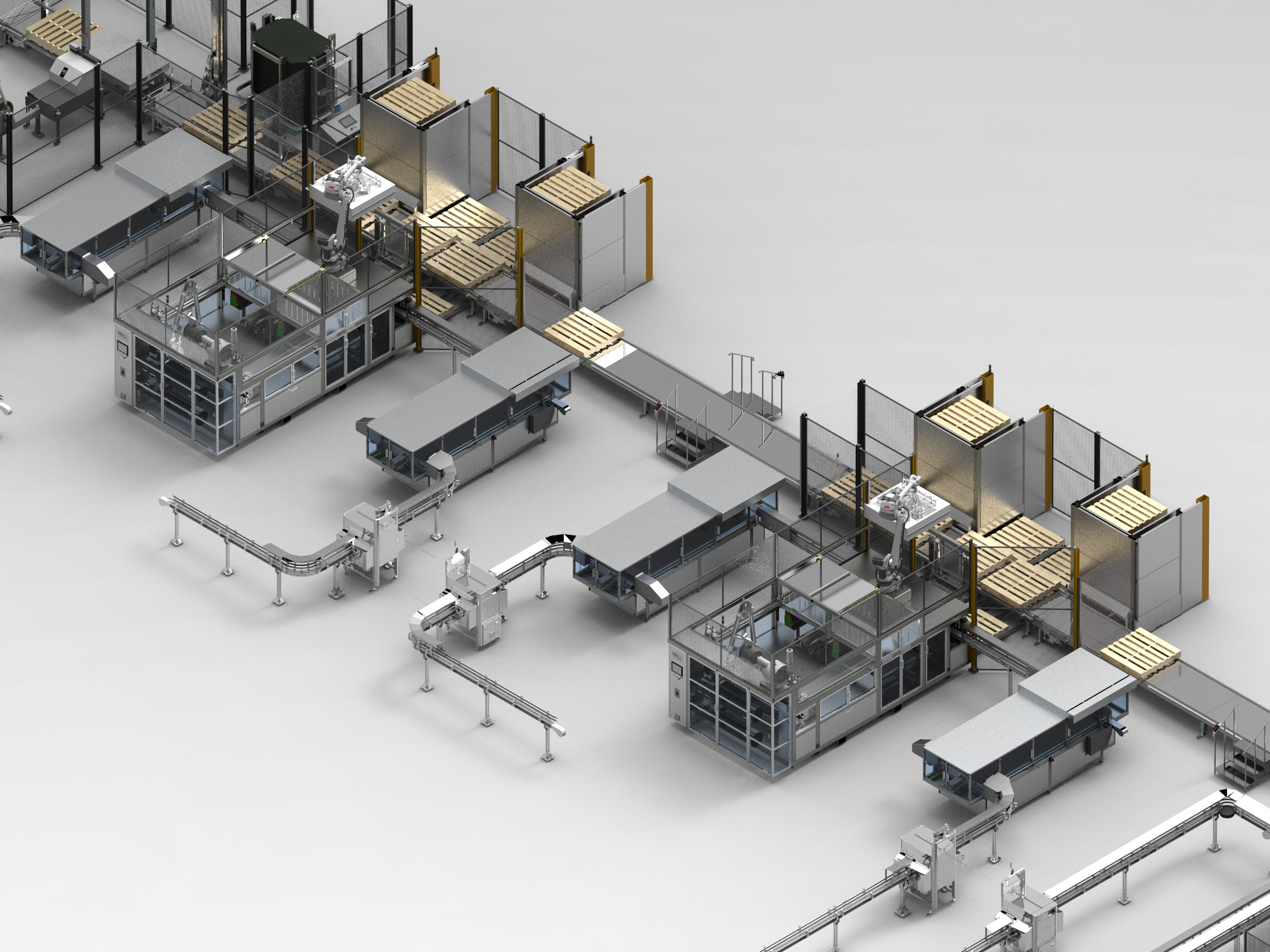

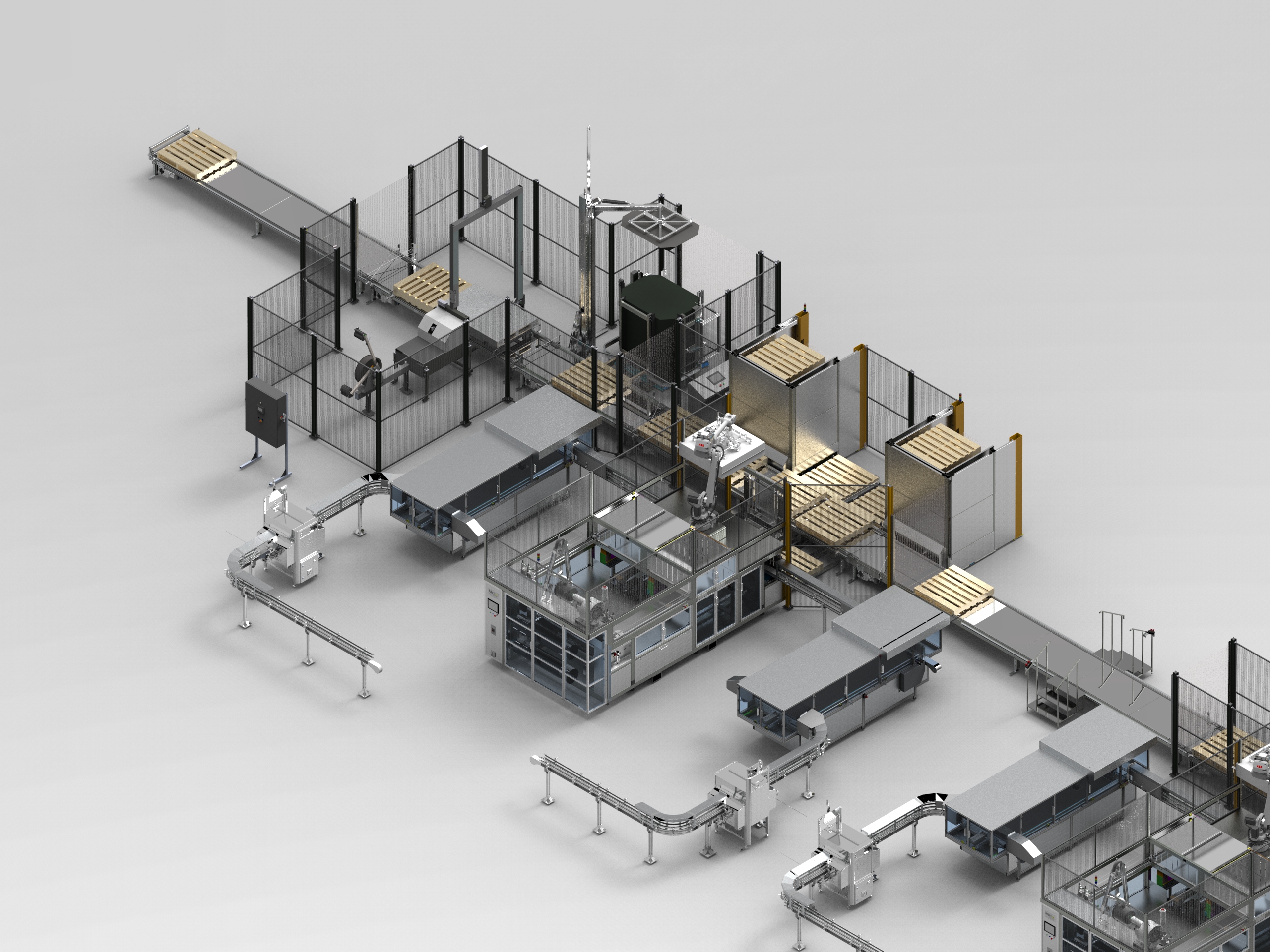

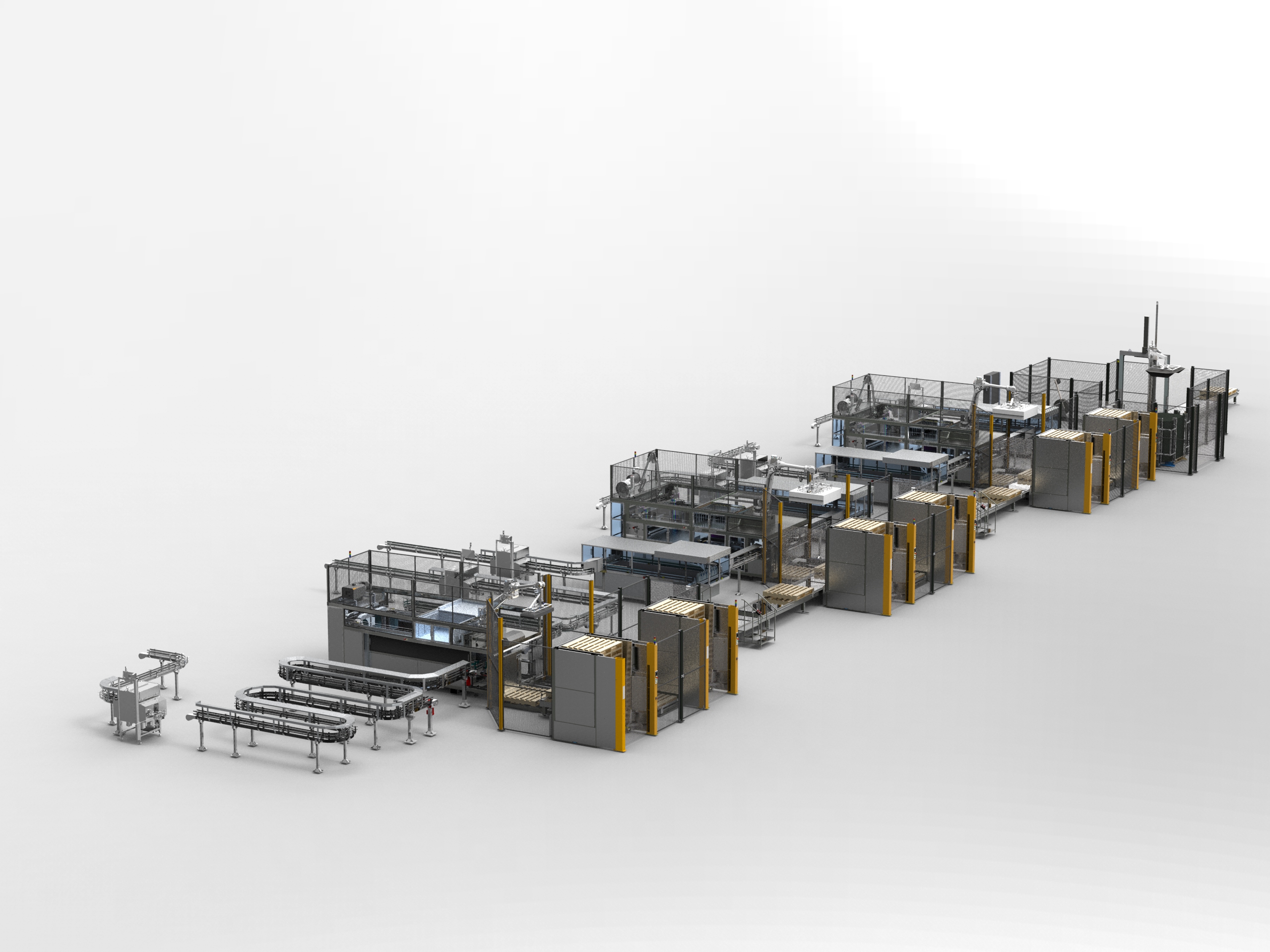

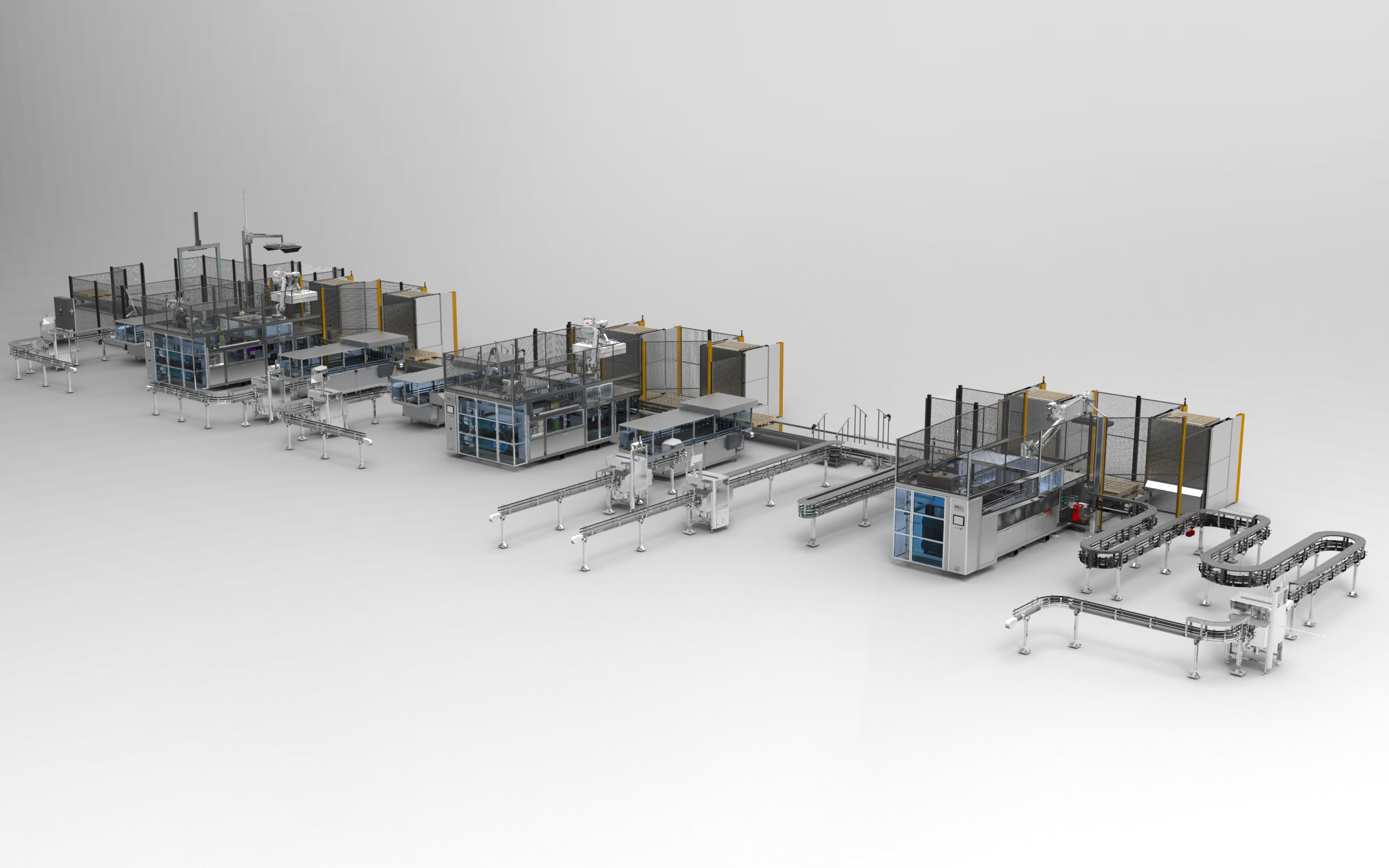

Complete Turnkey Bottle Packaging and Delivery System

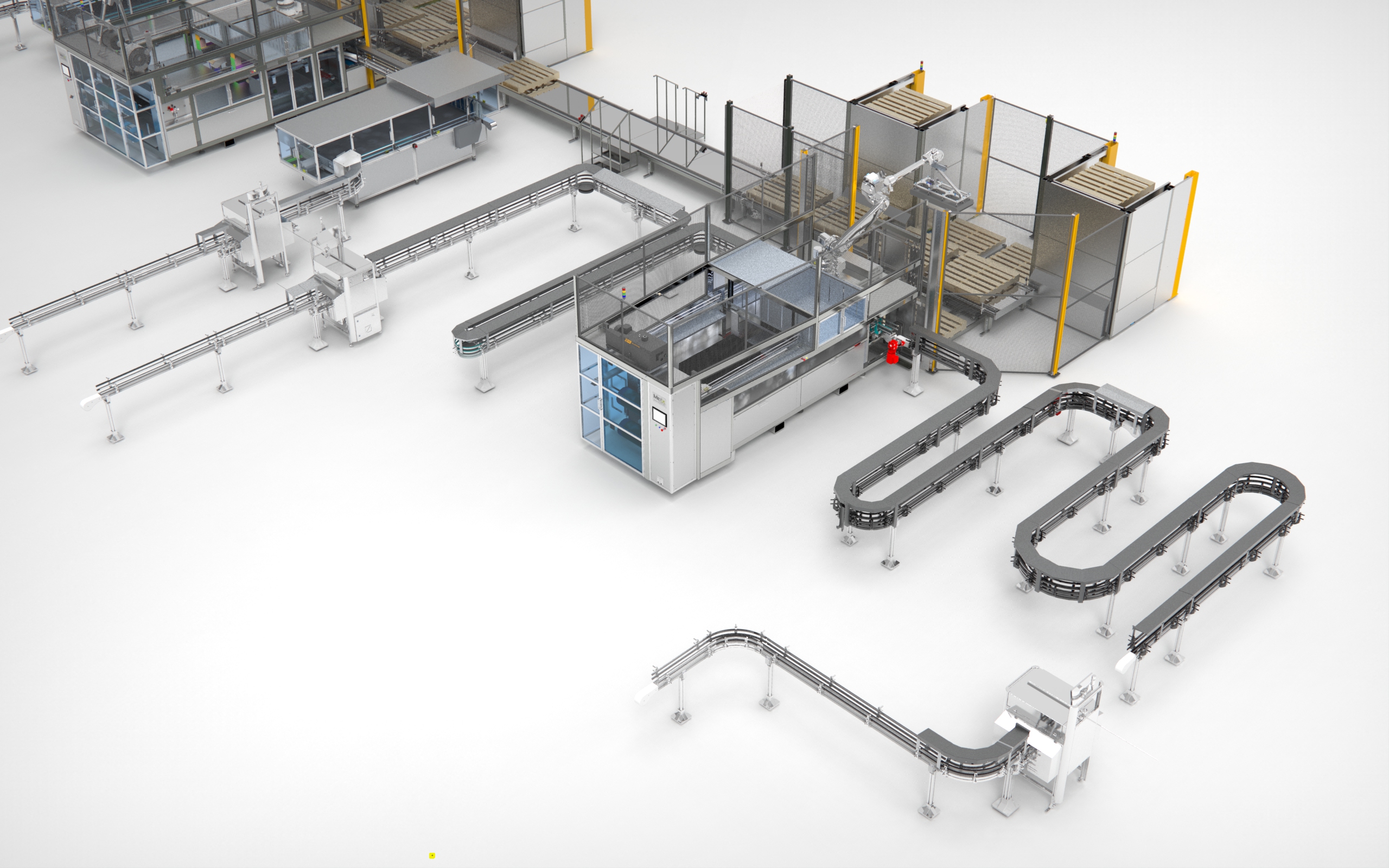

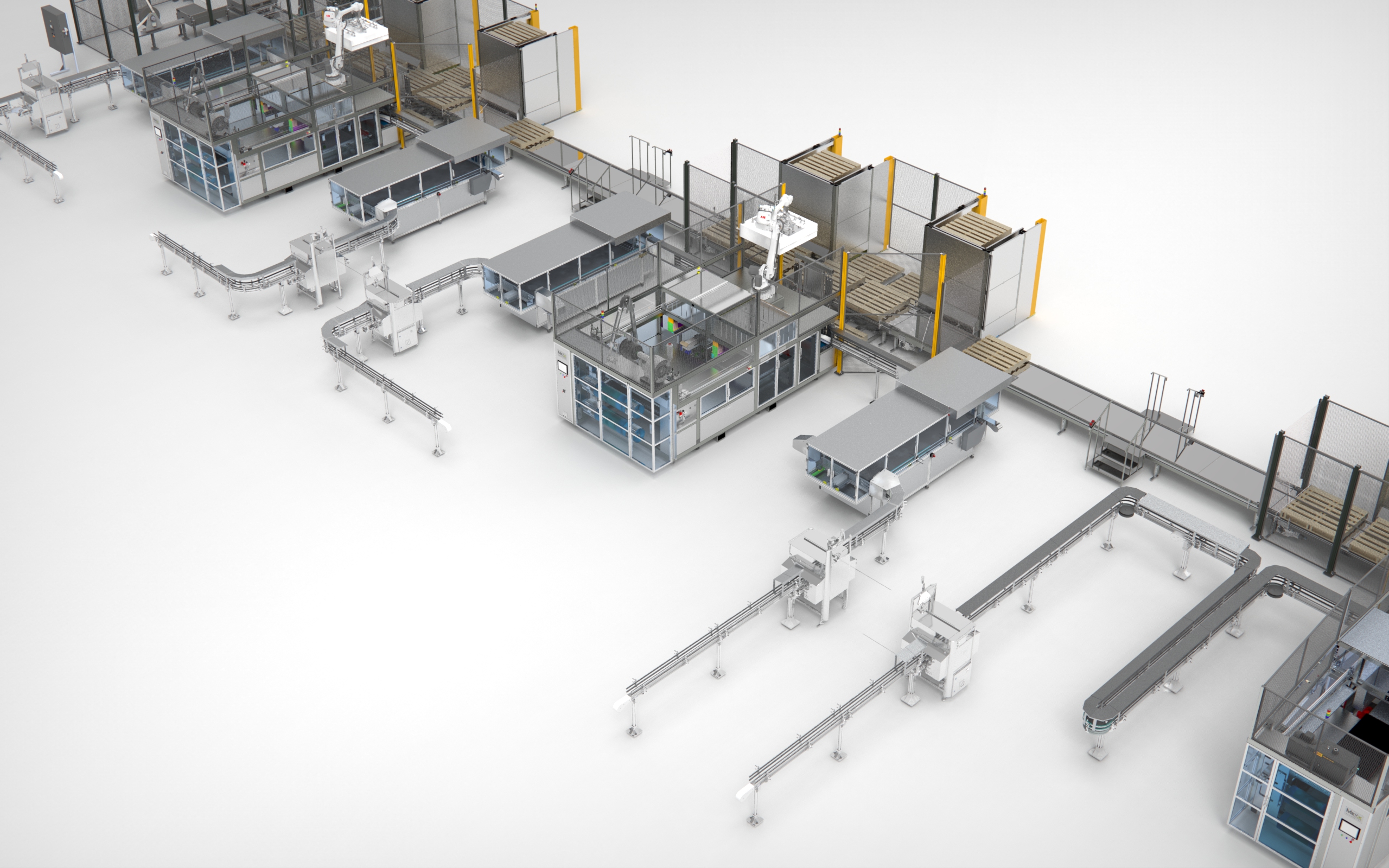

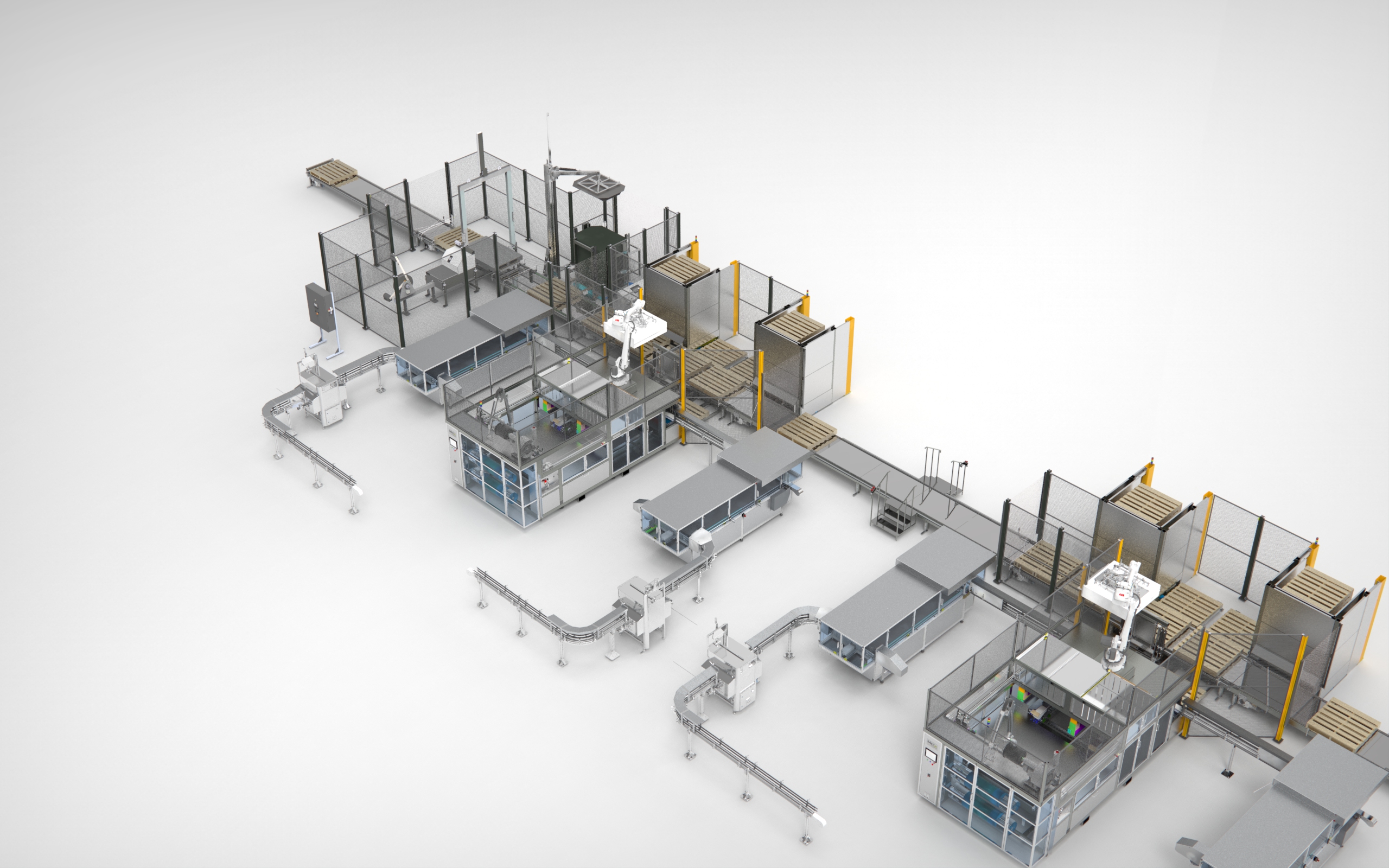

The complete bottle delivery system consists of the bottle packaging and palletising system with an independent bottle delivery system to the filler. The system depicted below illustrates the packaging system that is connected to 6 blow moulding machines. Each line has 6 vision systems, 6 automatic pallet destackers, a top frame pad placing system and fully automated pallet strapping system. The debagging and bottle delivery system consisted of 2 independent debagger systems and 200 meters of stainless steel conveyor supplying bottles to 2 independent high speed filling lines.

Complete Turnkey Bottle Packaging and Delivery System (Slideshow)

***This is a partial image of the actual turnkey system.***

KEY FEATURES OF COMPLETE TURNKEY BOTTLE PACKAGING AND DELIVERY SYSTEM:

- 6 vision systems

- 6 automatic pallet destackers

- 2 independent debagger systems

- 200 meters of stainless steel conveyor

- Top frame pad placing system

- Fully automated pallet strapping system

- System safety interlocked and guarded as per Australian and New Zealand Standards

HOW DOES IT WORK?

This turnkey system is built for efficiency, reliability, and high-performance.

The complete bottle delivery system consists of the bottle packaging and palletising system with an independent bottle delivery system to the filler. The packaging system that is connected to 6 blow moulding machines. Each line has 6 vision systems, 6 automatic pallet destackers, a top frame pad placing system and fully automated pallet strapping system. The debagging and bottle delivery system consisted of 2 independent debagger systems and 200 meters of stainless steel conveyor supplying bottles to 2 independent high speed filling lines.

The machine is also designed with industry 4.0 in mind. It's equipped to handle automatic guided vehicle or AGV. An AGV is a mobile robot that follows markers or wires in the floor or uses vision or lasers. They are often used in industry 4.0 to move stacks of bagged bottles or stack of layer pads around a manufacturing facility.

Bottle Packaging and Palletising System (partial image only)

Bottle Packaging and Palletising System (partial image only)

APPLICATIONS FOR THIS TURNKEY SYSTEM

The integration of high-end turnkey system can increase productivity or efficiency within the following industries:

TURNKEY SYSTEM

This turnkey system has a built-in:

- a vision system that detects the bottle size

- a conveyor system that will transport the bottles from each blow moulding machine into the filler

- a debagger

- a pallet stacker

- a pallet strapper

As a turnkey system, it is a fully automated system where the following components are purposely added to create this sophisticated machine:

- Debagger system

- Pallet Stacker

- Conveyor system

- Vision system

DESIGN AND BUILD PERIOD

This turnkey system may take around 12 months from purchase order to delivery. The project timeline might vary depending on the customer's requests and specifications.

SERVICE MAINTENANCE

Service maintenance is any work necessary to keep all customer facilities in good repair and operating condition. It includes maintaining and repairing essential components of a machine. This excludes explicitly new work and alterations such as:

- manufacturing and modifying machines and complete lines

- providing decorative treatments

- modifying vision systems

- attaching or extending items to the machine.

WARRANTY

All of Mexx Engineering® machines and turnkey systems come with a minimum of one year warranty on workmanship and materials.

Each system developed by Mexx Engineering® is a seamless automated machine that minimises environmental impact and maximises performance while ensuring the safety of its operator.

For more information, please contact 07 5571 5733 and choose option 1 for sales, to discuss the best combination of equipment and system maintenance to suit your application.